Part 1 Photovoltaic bracket

(光伏支架)

1) For ground power stations, if the installation site is loose soil, a concrete base is generally used, and the concrete base is mainly a column foundation. For hard soil, a concrete base or screw piles can be directly driven into the ground.

2) For the concrete column foundation ground power station, its bracket components are very similar to the concrete roof power station.

3) For a concrete roof power station, if it is a new building, the parts can be embedded when pouring the concrete roof; if it is an existing building, the base can be installed with cement briquette load-bearing, strip foundation and column foundation.

4) For the metal roof, the corresponding fixing method should be selected according to the structure of the metal roof, such as stainless steel clamping blocks, double-ended screws and special guide rail fixing methods, etc.

Installation form of distributed photovoltaic power station

Distributed photovoltaics are mainly installed in industrial and commercial plants, rural roofs, etc. The main types of houses are reinforced concrete roofs,

Steel structure color steel plate roof, tile roof, parking shed and BIPV, etc. The design of distributed photovoltaics needs to design the appropriate inclination angle, orientation, installation form and node connection form according to the different attachments.

(1) Installation form of reinforced concrete roof photovoltaic array

Reinforced concrete roofs are generally divided into two types: access roofs and non-access roofs. The design bearing capacity of the access roof is 200kg/m2, and the design bearing capacity of the non-access roof is 50kg/m2.

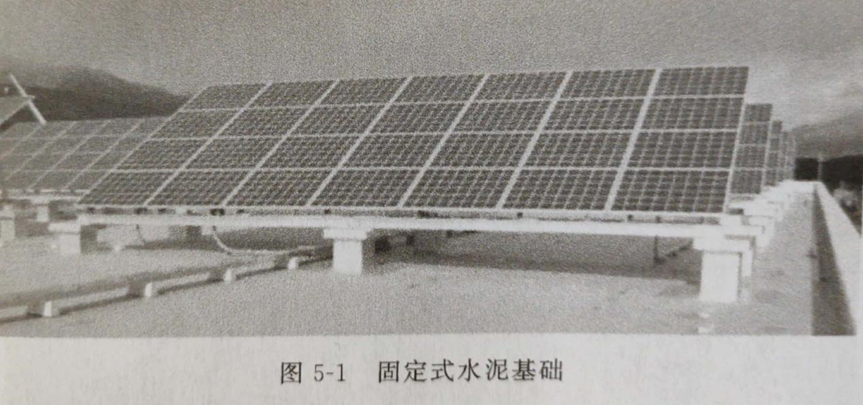

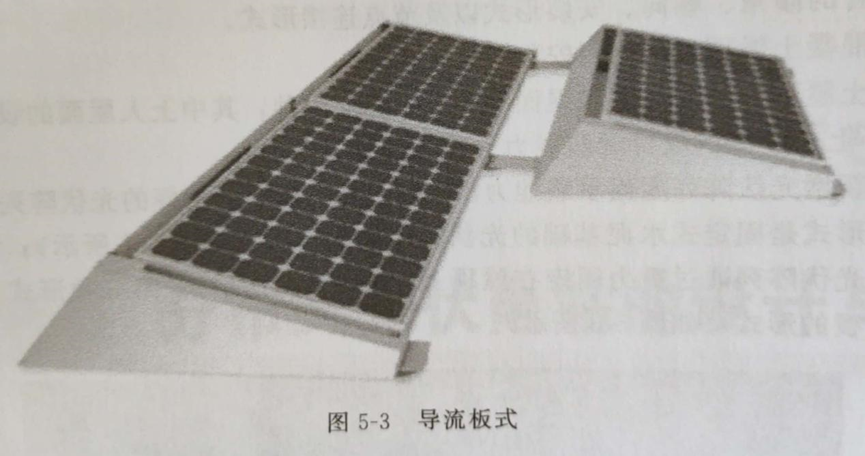

There is no problem with the bearing capacity of the newly added photovoltaic array on the roof. There are mainly two forms of photovoltaic arrays that can be selected for this type of roof: the first form is the installation of fixed cement-based photovoltaic arrays (as shown in Figure 5-1). ); the second form is to use counterweight blocks to fix the photovoltaic display on the roof by gravity (as shown in Figure 5-2); the third form is to install a deflector behind a small inclination (as shown in Figure 5-2). 3 shown).

1)对于地面电站,如果安装地为疏松土质,一般采用混凝土底座,混凝土底座以柱形基础为主,对于坚硬土质可采用混凝土底座或直接使用螺旋桩直打入地面以下。

2)对于混凝土柱形基础型地面电站,其支架组成部分与混凝土屋面电站有很大相似之处。

3)对于混凝土屋面电站,如果是新建房,可以在浇制混凝土屋面时预埋件;如果是现有建筑,其基座可考虑采用水泥压块负重、条形基础、柱形基础安装。

4)对于金属屋面,要根据金属屋面的结构选择相应的固定方式,有采用不锈钢夹块、双头螺杆以及特殊的导轨固定方式等,

分布式光伏电站的安装形式

分布式光伏主要安装在工商业厂房、农村屋顶等,主要的屋项类型有钢筋混凝士屋顶、

钢结构彩钢板屋顶、瓦屋顶、停车棚以及BIPV等。分布式光伏的设计需要根据附着物的不同,来设计适合的倾角、朝向、安装形式以及节点连接形式。

(1)钢筋混凝土屋顶光伏阵列安装形式

钢筋混凝土屋顶一般分为上人屋面和不上人屋面两种,其中上人屋面的设计承载能力为200kg/m2,不上人屋面的设计承载能力为50kg/m2。

上人屋面新增光伏阵列屋面承载能力没问题,此类屋面可选择的光伏阵列的形式主要有两种:第一种形式是固定式水泥基础的光伏阵列安装形式(如图5-1所示);第二种形式是采用配重块将光伏陈列通过重力固定在屋顶上(如图5-2所示);第三种形式是采用小倾角背后安装导流板的形式(如图5-3所示)。

The fixed foundation is connected to the roof beam through steel bars. The foundation is relatively firm and can withstand the tensile load generated by the large negative wind pressure. This type of installation can design the photovoltaic array to an inclination angle for the best power generation, but this structural form The cement foundation needs to be located on the beams of the roof and connected to the roof beams through steel bars. The waterproofing of the cement foundation also needs to be integrated with the roof. The roof structure layer is exposed, and the chemical planting reinforcement is fixed with the original roof structure layer (as shown in Figure 5-4), and then the reinforcement cage and cement foundation are made, and the damaged waterproof and thermal insulation part is repaired after completion (as shown in Figure 5-5 shown).

固定式基础通过钢筋与屋顶梁连接,基础比较牢固,能够承受较大的负风压产生的拉力载荷,此类安装形式可将光伏阵列设计成最佳发电量的倾斜角度,但这种结构形式的水泥基础需要坐落在屋顶的梁上,并通过钢筋与屋顶梁连接,水泥基础的防水也需要与屋顶做成一体,如果是已投人使用的屋面,需要将原屋面的防水保温层局部切割掉,露出屋顶结构层,将化学植筋与原屋顶结构层固定(如图5-4所示),然后制作钢筋笼和水泥基础,完成后再将破坏的防水保温部分进行修复(如图5-5所示)。

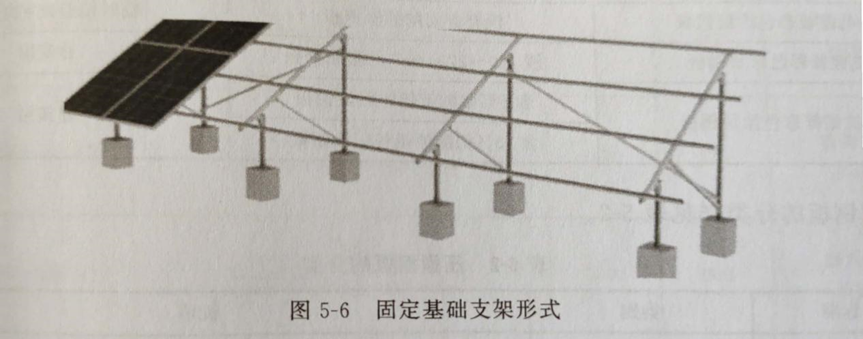

Fixed cement-based photovoltaic array supports are suitable for hot-dip galvanized carbon steel supports. The fixation between photovoltaic supports and cement foundations can be in the form of pre-embedded fixtures for cement foundations or chemical planting. The rear side diagonal support to prevent crosswind should be added to the photovoltaic array (as shown in Figure 5-6). The design life of the photovoltaic power station should reach 25 years, the thickness of the galvanized layer of the photovoltaic support should not be less than 60μm, and the fasteners should be hot-dip galvanized or stainless steel SUS304. If the selected brackets or fasteners have insufficient anti-corrosion ability, corrosion will occur and spread continuously after several years of use, affecting the service life and strength.

固定式水泥基础光伏阵列支架适宜选用热浸锌碳钢支架,光伏支架与水泥基础之间的固定,可选择水泥基础预埋固定件的形式,也可以选择化学植筋的形式。光伏阵列的应增加防侧风的后侧斜支撑(如图5-6所示)。光伏电站的设计寿命应达到25年,光伏支架镀锌层厚度不应低于60μm,紧固件应选用热浸锌或者不锈钢SUS304的。若所选支架或紧固件防腐能力不够,使用几年后将产生锈蚀并不断扩散,影响使用寿命及强度。

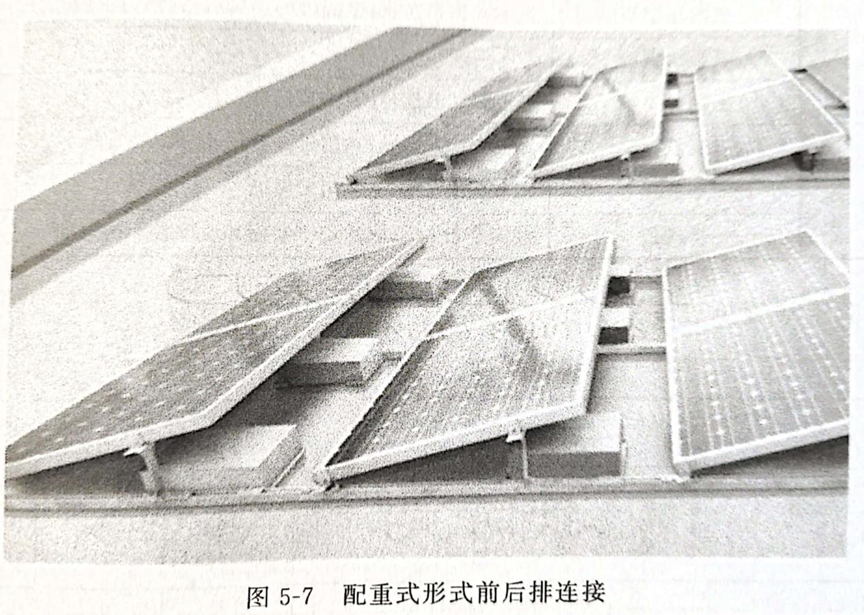

There is no direct connection between the photovoltaic array and the roof in the form of counterweight, but only through gravity to resist the pulling force of the photovoltaic array in the case of negative wind pressure. Therefore, this installation form is not enough to withstand large wind loads. This type of fixing is not suitable for the environment, the roof with a high height and the large tilt angle of the photovoltaic array. The advantage of this counterweight fixed form is that the pre-supported cement block is used as the counterweight, which does not damage the original roof waterproof and thermal insulation layer, and the construction period is short. However, the inclination angle of the photovoltaic array in this installation form should not exceed 20 degrees. The quality and arrangement of the counterweight should fully consider the wind resistance and the overall structural stability of the photovoltaic array when it is exposed to wind. Considering that the photovoltaic array is subject to negative wind pressure, which affects the overall stability, the front and rear rows of the photovoltaic array need to be connected together by brackets (as shown in Figure 5-7), so that the rear column feet should not be lifted under the condition of negative wind pressure. or move. In the design of counterweight fixed form, it is important to fully consider the wind load in the design of the counterweight. The wind force at the rear column foot is relatively large, and the area around the building roof will generate turbulent airflow. When the weight is 1.3 times the weight, it is beneficial to increase the overall wind resistance.

配重形式光伏阵列与屋顶之间没有直接连接,只是通过重力来抵御光伏阵列在负风压的情况下承受的拉力,所以,这种安装形式不足以抵御较大的风荷载,在地域空旷的环境、高度较高的屋顶以及较大的光伏阵列倾斜角度的情况下,不宜采用此种固定形式。这种配重式固定形式的优点是采用预支水泥块作为配重物,不破坏原屋面防水保温层,施工周期短。但这种安装形式光伏阵列的倾斜角度不宜超过20度,配重块的质量及排布要充分考虑抗风和光伏阵列受风时的整体结构稳定性。考虑到光伏阵列受到负风压,影响整体稳定性,光伏阵列前后排之间需要通过支架连接成整体(如图5-7所示),这样在负风压情况下,后柱脚不宜抬起或移动。在配重式固定形式设计时,设计配重要充分考虑风荷载,后柱脚处受风作用力较大,建筑屋顶四周区域会产生乱气流,配重设计时边缘区域配重质量达到其他区域配重质量的1.3倍时,有利于增加整体抗风能力。

Most of the counterweights are pre-supported cement blocks, and the single size design of the cement blocks should fully consider the form of the support. Lay down stability and construction operability. If a single counterweight is too heavy, it will cause inconvenience to construction and handling, and the internal reinforcement of the counterweight will prevent it from breaking in the future. There are two common ways to fix the bracket and the counterweight: one is to press the counterweight on the bracket, which ensures stability; the other is that the bracket is fixed on the bracket by chemical planting. On heavy blocks, this method is more stable in extreme environments.

For the photovoltaic array, a small inclination angle is used, and the deflector is installed behind it. Under the action of wind load, it is converted into horizontal and downward forces, and there is no upward pulling force. It avoids the upward pulling force generated by the photovoltaic array when it receives negative wind pressure, and cleverly uses the deflector to convert the wind pressure into forward and downward force. Therefore, this type of installation does not require excessive counterweight. The inclination angle of this installation form is generally not more than 10 degrees, and the entire photovoltaic array is connected in the front and rear rows. This installation form does not exceed 30kg per square meter for the new static load on the roof, which is far lower than the installation form of counterweight. Concrete roof is limited by its bearing capacity and can only be installed in this form.

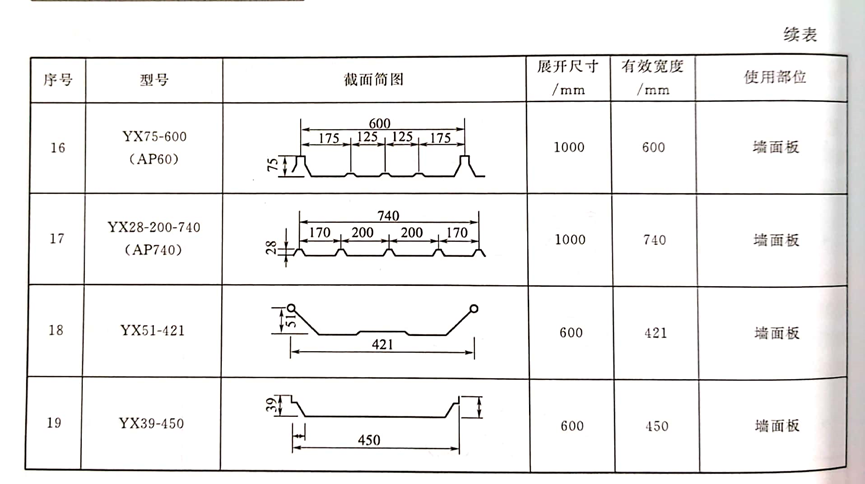

(2) Photovoltaic array installation form of steel structure color steel plate roof

With the rapid development of distributed photovoltaics, industrial and commercial roofs have become the main construction carriers of distributed photovoltaic power stations. About 70% of industrial and commercial buildings are in the form of steel structure color steel plates. Compared with reinforced concrete buildings, steel structure color steel plate buildings have low cost, Due to the advantages of short construction period, it is suitable for large-scale industrial buildings. There are various forms of color steel plates. The classification of color coated steel plates is shown in Table 5-1. Color steel plate coating is divided into primer and topcoat. Primer is divided into epoxy primer, polyester primer, acrylic primer and polyurethane primer; topcoat is divided into polyester (PE) and polyvinylidene fluoride (PVDF). ).

Table 5-1 Classification of Color Coated Steel Plates

type | illustrate | use |

Cold Rolled Substrate Color Coated Steel Plate

| Color-coated steel sheet without coating | Temporary facilities or indoor use |

| Hot-dip galvanized color coated steel sheet | Color coated steel plate plated with 180~270g/m2 | for construction |

| Hot-dip galvanized color coated steel sheet | Galvalume color-coated steel sheet containing 5% aluminum | for construction

|

| Galvalume color-coated steel sheet containing 55% aluminum |

Table 5-2 Classification of profiled steel plates

| Classification criteria | category | illustrate |

|

By use | Layer pressing plate | The basic function is waterproof, the connection of the layer version has lap joint and hidden joint |

| wall panel | ||

| floor panel | Separate open type and closed type (dovetail profiled steel plate)

| |

|

By shape | High wave plate | Wave height 50~75mm, suitable for floor slab, roof and wall |

| Medium wave board | Wave height greater than 75mm, suitable for roofing | |

| low wave board | The wave height is less than 50mm, suitable for walls and roofs with large slopes |

配重物较多采用预支水泥块,水泥块的单体尺寸设计应充分考虑支架形式。放詈稳定性以及施工可操作性。单个配重块过重会给施工和搬运造成不便,配重块内官配筋,避免将来破碎。支架与配重块的固定常见两种形式:一种形式是将配重块压在支架上,这种压的形式要确保稳定性;另一种形式是支架通过化学植筋的形式固定在配重块上,这种方式在极端环境下更加稳固。

对于光伏阵列采用小倾角,背后安装导流板的形式,在受到风荷的作用下,都转化成水平和向下的力,不存在向上的拉力。避免了光伏阵列在收到负风压时产生的向上拉力,并巧妙地利用导流板将风压转化成向前和向下的力。所以,这种安装形式不需要过多的配重。这种安装形式倾角一般不超过10度,整个光伏阵列前后排连接,这种安装形式对于屋顶新增静荷载单位平米不超过30kg,远远低于配重的安装形式,所以,对于不上人水泥屋面受限于其承载能力,只能采用这种安装形式。

(2)钢结构彩钢板屋顶的光伏阵列安装形式

随着分布式光伏迅猛发展,工商业屋顶成为分布式光伏电站的主要建设载体,工商业建筑中70%左右的建筑形式为钢结构彩钢板形式,钢结构彩钢板建筑相对于钢筋混凝土建筑具有成本低、建设周期短等优点,适合大型工业建筑,彩钢板的形式多种多样,彩色涂层钢板的分类详见表5-1。彩钢板涂层分为底漆和面漆,底漆分为环氧底漆、聚酯底漆、丙烯酸底漆以及聚氨酯底漆;面漆分为聚酯(PE)和聚偏氟乙烯(PVDF)。

表5-1 彩色图层钢板的分类

类型 | 说明 | 用途 |

| 冷轧基板彩色涂层钢板 | 没有镀层的彩涂钢板 | 临时设施或室内使用 |

| 热镀锌彩色涂层钢板 | 镀180~270g/m2的彩涂钢板 | 建筑用 |

| 热镀铝锌彩色涂层钢板 | 含5%铝的镀铝锌彩涂钢板 | 建筑用

|

| 含55%铝的镀铝锌彩涂钢板 |

压型钢板的分类详见表5-2.

表5-2 压型钢板的分类

| 分类标准 | 类别 | 说明 |

|

按用途分 | 层面压型板 | 基本功能是防水,层面版的连接有搭接式连接和隐藏式连接 |

| 墙板压型板 | ||

| 楼面压型板 | 分开口式和闭口式(燕尾压型钢板) | |

|

按造型分 | 高波板 | 波高50~75mm,适用于楼盖板、屋面和墙面 |

| 中波板 | 波高大于75mm,适用于屋面 | |

| 低波板 | 波高小于50mm,适用于墙面和坡度较大的屋面 |

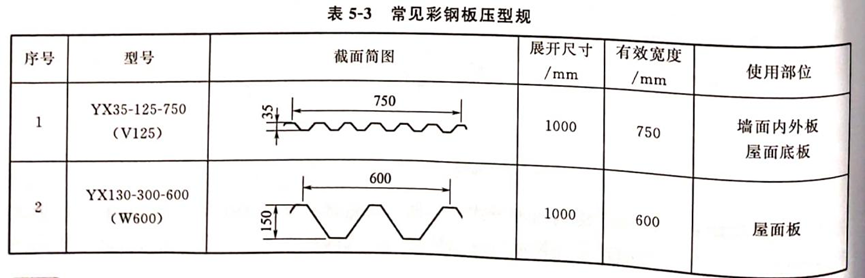

See Table 5-3 for common color steel plate pressure gauges

常见彩钢板压型规见表5-3

Distributed photovoltaic design needs to fully understand the specifications and dimensions of the roof panel. In addition, it is also necessary to consider the current situation of the roof, including the age of the roof panel, the age of the roof, the remaining service life, and the rusted roof surface. The roof needs to be rusted and anti-corrosion treated. The reserved load of the steel structure roof is small. Therefore, the structural design institute needs to check the bearing capacity of the original building structure when adding photovoltaic arrays on the roof. If the building bearing capacity is insufficient, the original structure needs to be reinforced or the photovoltaic array should be arranged Adjustment. The photovoltaic array and the color steel plate are generally connected by a fixture, and the fixture is fixed on the color steel plate. It can be clamped on the corrugated by the clamp without damaging the color steel plate, and the trapezoidal plate can be fixed on the roof panel by bolts. The common fixture types are shown in Figure 5-9. If there is no ready-made fixture for the size of the roof panel corrugation, you can measure the detailed size of the corrugated on the spot, and open the mold to make the fixture according to the size. When choosing a roof panel fixture, it is not only to determine the type of fixture, but also to bring the fixture to the site for a locking test to confirm whether the size of the fixture and the roof panel is appropriate. In addition, it should be noted that it is possible to use two or more types of fixtures for one roof.

分布式光伏设计需充分了解屋面板的规格尺寸,除此之外,还需要考虑屋顶的现状情况,包括屋面板已经使用的年限,屋顶老旧情况,剩余使用寿命,对于屋顶表面有锈蚀的,需要对屋顶进行除锈和防腐处理。钢结构屋顶预留荷载较小,所以,屋顶新增光伏阵列需要结构设计院对原建筑结构的承载能力进行校核,如果建筑承载能力不足,需要对原结构进行加固或者将光伏阵列排布进行调整。光伏阵列与彩钢板一般通过夹具连接,夹具固定在彩钢板楞上,彩钢板的楞通常分为角驰、直立锁边和梯形(如图5-8 所示),角驰和直立锁边都可以通过夹具夹在楞上,不破坏彩钢板,梯形板通过螺栓将固定件固定在屋面板上。常见夹具类型详见图5-9,如果屋面板楞的尺寸没有现成可以选用的夹具,可以现场测量楞的详细尺寸,根据尺寸进行开模制作夹具。在选用屋面板夹具时,不仅仅是确定夹具类型,需要将夹具带到现场进行锁紧测试,确认夹具与屋面板楞的尺寸是否合适。另外,需要注意的是,有可能一个屋面用到两种类型及以上的夹具。

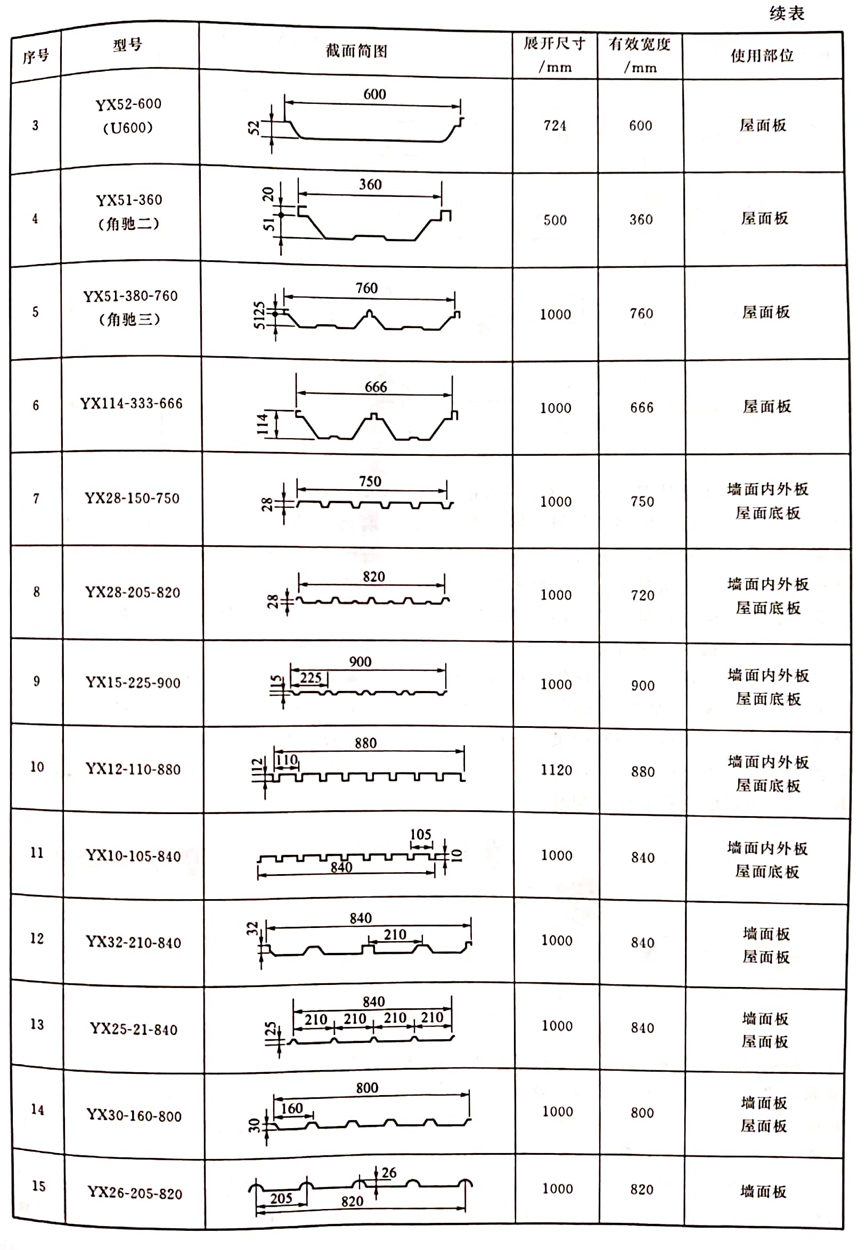

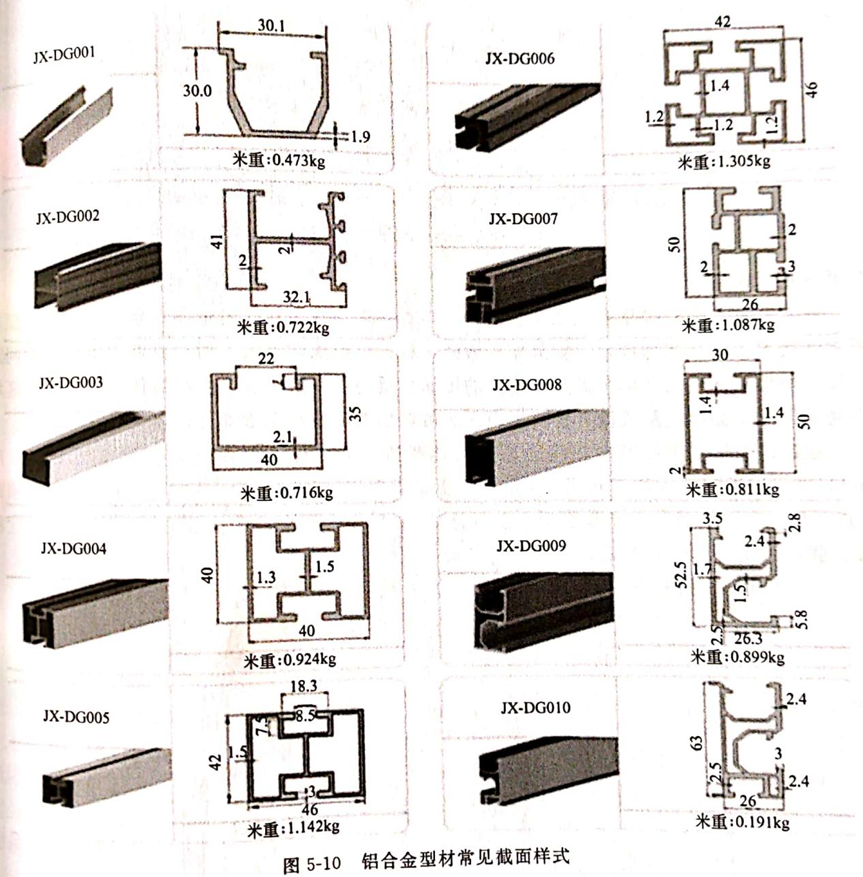

The brackets used for the color steel plate roof photovoltaic array are generally made of aluminum alloy, which is mainly lighter in weight than carbon steel, which can reduce the added static load per square meter of the original building. The interface style of aluminum alloy profiles Photovoltaic bracket manufacturers have carried out lightweight optimization designs based on experience, saving materials and reducing costs. The common cross-sectional forms of aluminum alloy profiles are shown in Figure 5-10. The selection of specific hidden surface forms depends on the installation form. and easy to operate.

彩钢板屋顶光伏阵列选用支架一般采用铝合金材质的,主要是质量比碳钢的要轻,能够降低原建筑单位平米新增的静荷载。铝合金型材的界面样式光伏支架厂家都根据经验进行了轻量化优化设计,更加节省材料、降低成本,铝合金型材常见的截面形式详见图5-10.具体藏面形式的选用,根据安装形式和操作的方便进行设计。

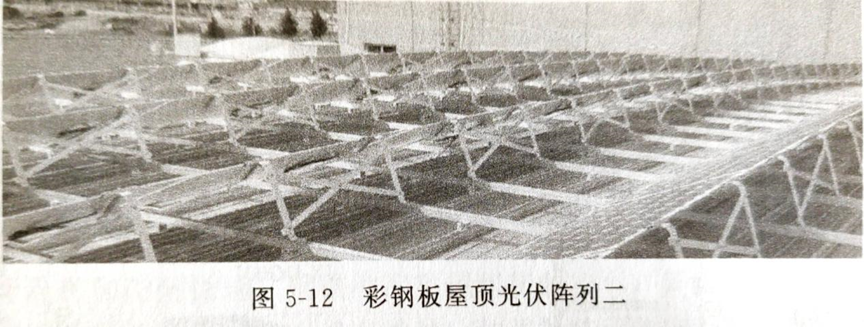

The color steel roof generally has a flooding slope of 5 degrees. The common installation method of the photovoltaic array on the color steel roof is to lay parallel to the roof (as shown in Figure 5-11). Set a certain inclination angle facing south (as shown in Figure 5-12), but limited by the bearing capacity of the color steel tile roof, the design of the inclination angle of the photovoltaic array should be fully demonstrated. Under pressure or tension, the bearing capacity of the original steel structure and roof panel should be checked.

彩钢板屋顶一般有5度的泛水坡度,光伏阵列在彩钢屋顶上的常见安装方式是与屋顶平行铺设的形式(图5-11 所示),也有些项目为提高发电量,将光伏阵列朝南设置一定的倾角(图5-12 所示),但受限于彩钢瓦屋的承载能力,光伏阵列设计倾斜角度时要经过充分论证,光伏阵列与屋顶间设计夹角,在风荷载作用下,会产生压力或拉力,要校核原钢结构及屋面板的承载能力。

After selecting the color steel tile fixture type and purlin type, the T-type fixture needs to be driven into the roof panel by bolts, and a waterproof rubber pad needs to be added between the fixture and the roof panel. If the construction effect is not good, you need to apply waterproof glue. The fixed distance between the two fixtures directly affects the strength of the purlin and the force of the roof panel at the fixing point of a single fixture, generally about 1.2m is better. The edge area of the building will generate turbulent airflow under the condition of wind, and the number of fixtures can be increased in the surrounding area of the building to increase the wind resistance of the photovoltaic array.

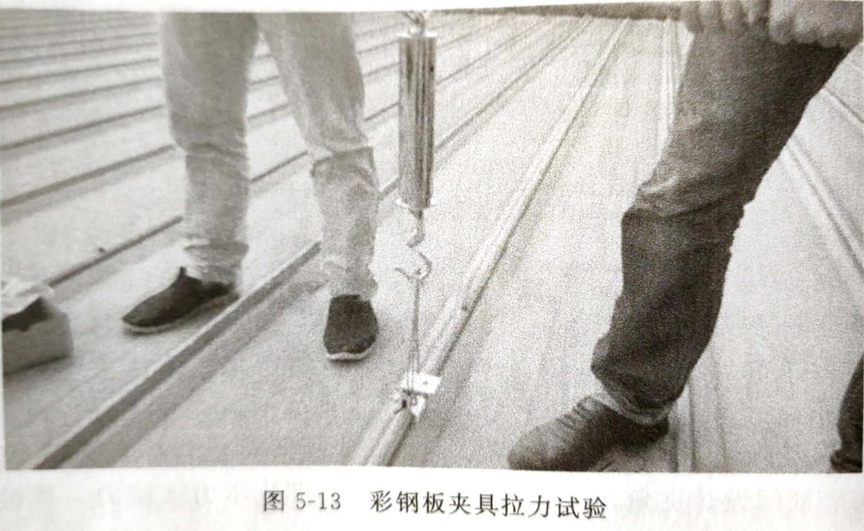

When determining the details of the photovoltaic support, bring a suitable fixture to the roof for assembly and tensile test (as shown in Figure 5-13), and test points at different places, such as 1 point at the color steel purlin, 1 point at the edge, 1 point in the middle and 1 point at the top of the color steel tile. The single-point tensile force of the roof panel and fixture should reach more than 60kg. If the tensile force cannot be supported, the strength should be checked. If the strength does not meet the design requirements, a fixed point should be added.

选定彩钢瓦夹具类型和檩条类型后,T型夹具需要通过螺栓打进屋面板,在夹具与屋面板之间需要增设防水橡胶垫。如果施工效果不好,需要涂防水胶。两个夹具之间的固定间距直接影响檩条的强度和单个夹具固定点的屋面板受力,一般1.2m左右为佳。建筑边缘区域在受风情况下会产生乱气流,建筑周边区域可增加夹具数量来增加光伏阵列的抗风能力。

在确定光伏支架细节时,将适合的夹具带到屋顶进行装配和拉力试验(如图5-13所示),在不同地方分别取点测试,如彩钢瓦檩条处1点、边缘1点、中间1点及彩钢瓦顶部1点。屋面板及夹具的单点承受拉力要到达60kg 以上,若无法承受该拉力,应进行强度校核,强度不满足设计要求是,应增加固定点。

(3) Photovoltaic array installation form of tile roof

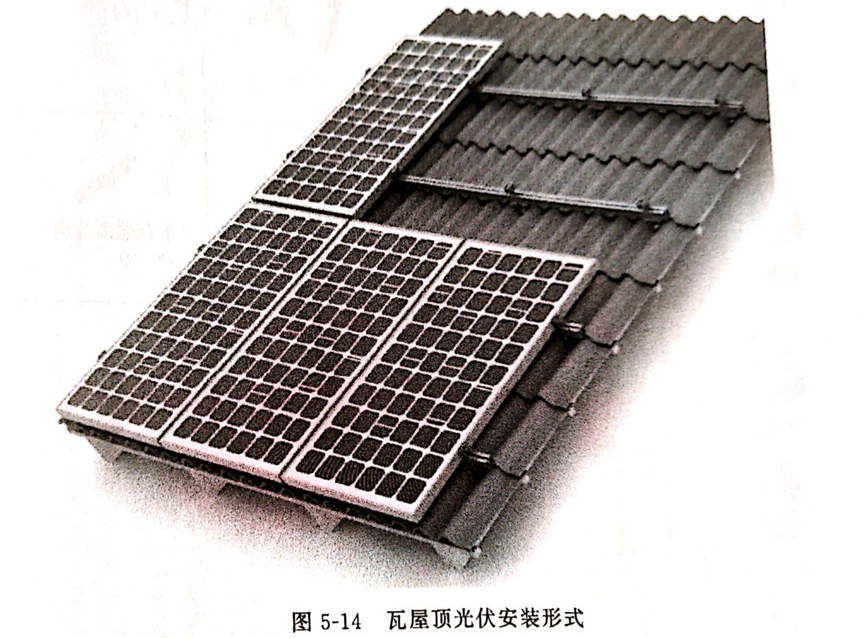

With the rapid development of photovoltaics, the heat of the rural photovoltaic market is developing rapidly, and photovoltaic poverty alleviation has also become an effective way of targeted poverty alleviation. Some increase the initial installation fee subsidy, and some increase the electricity subsidy. Farmers' understanding of photovoltaic power generation has also changed from being out of reach to high-tech financial products. Most of the roofs of household photovoltaics are tile roofs. The tile roofs are connected to the internal structure of the roof through hooks and protrude from the upper and lower joints of the tiles (see Figure 5-14 and Figure 5-15 for details). The fixed point is in the building Structurally, it ensures the reliability of fixation, and at the same time does not damage the waterproof structure of the tile, which also ensures that the waterproof performance of the roof is not damaged.

(3)瓦屋顶的光伏阵列安装形式

随着光伏的迅速发展,农村光伏市场的热度在迅猛发展,光伏扶贫也成为精准扶贫的有效途径,为支持户用光伏的发展,有些地区的地方财政专门针对户用光伏出台丰厚的补贴政策,有些增加初装费补贴,有的增加度电补贴。农民对光伏发电的认识也从遥不可及转变成了高科技理财产品。户用光伏大部分屋顶为瓦屋顶,瓦屋顶通过挂钩与屋顶内部结构进行连接,并从瓦片的上下接缝处伸出来(详见图5-14及图5-15),固定点在建筑结构上,确保固定的可靠性,同时不破坏瓦的防水结构,也就确保了屋顶的防水性能不受破坏。

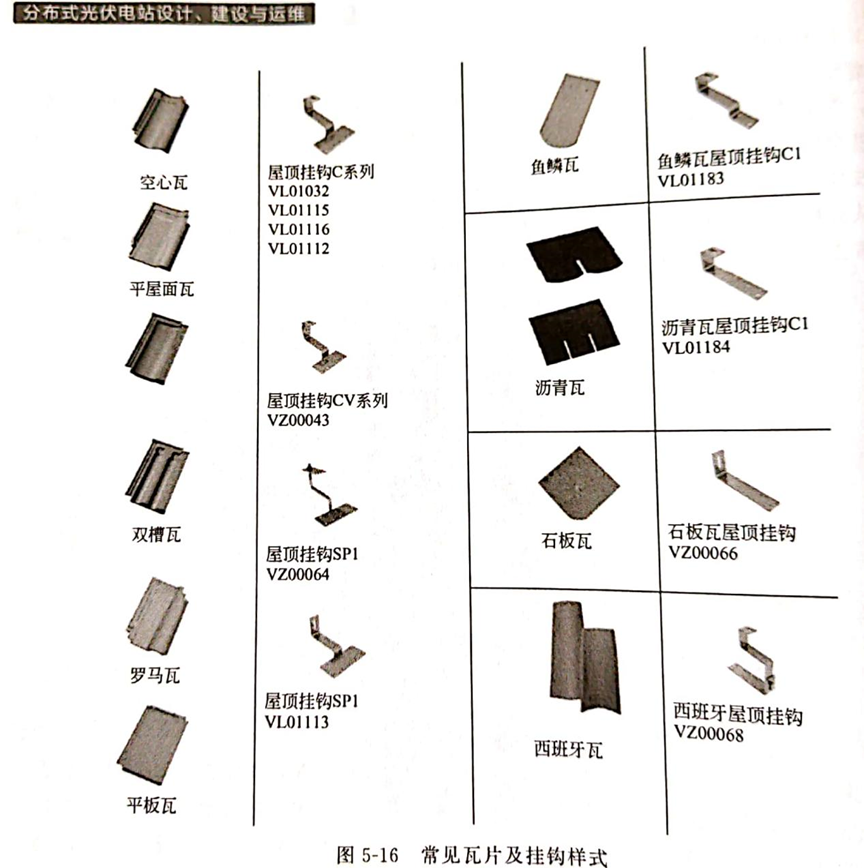

Different roof tiles and structures, the applicable hooks are also different in details. Common tile and hook styles are shown in Figure 5-16. The hooks are made of stainless steel SUS304 and hot-dip galvanized ordinary carbon steel. If The roof structure is in the form of wooden purlins, the hooks and the roof structure are fixed with wood screws, and each hook is fixed with at least three wood screws; if the roof structure is a concrete structure, chemical bolts are used between the hook and the predetermined structure, and two chemical bolts are used for each hook. bolt. Purlins are available in two forms: hot-dip galvanized carbon steel and aluminum alloy.

屋顶瓦片和结构的不同,所适用的挂钩也有些细节的不同,常见瓦片及挂钩样式如图5-16所示,挂钩的材质分为不锈钢SUS304和热镀锌普通碳钢两种,如果屋顶结构是木檩条形式,挂钩与屋顶结构选用木螺丝固定,每个挂钩至少固定三个木螺丝;如果屋顶结构是混凝土结构,挂钩与预定之间用化学螺栓固定,每个挂钩用两个化学螺栓。檩条可以选用热镀锌碳钢和铝合金两种形式。

(4) Photovoltaic installation form of parking shed

Photovoltaic carport is a system that combines photovoltaic power generation with carport. It can not only shield the vehicle from wind and rain, but also use solar energy to create clean photovoltaic energy for electric vehicle charging, lighting and integration into the power grid. The construction of this system has almost no geographical restrictions, is very flexible and convenient, and comprehensively utilizes space resources to develop new energy. Some car manufacturing companies have very large parking lots in the factory area, and some new cars are exposed to the sun and rain in the parking lot. The construction of photovoltaic parking sheds can not only realize distributed photovoltaic power generation, but also create a better environment for vehicle parking. As long as there is enough space, the photovoltaic carport can not only realize the benefits of green energy power generation, the functions that the shed cannot have, but also meet the functions that the conventional carport cannot have. With the development of different application technologies, it can charge electric vehicles. Charging electric bicycles is also becoming more and more realistic. Now more and more gas stations and service areas are installing distributed photovoltaic power generation parking sheds and electric vehicle charging piles. Really enjoy the convenience brought by green energy to life.

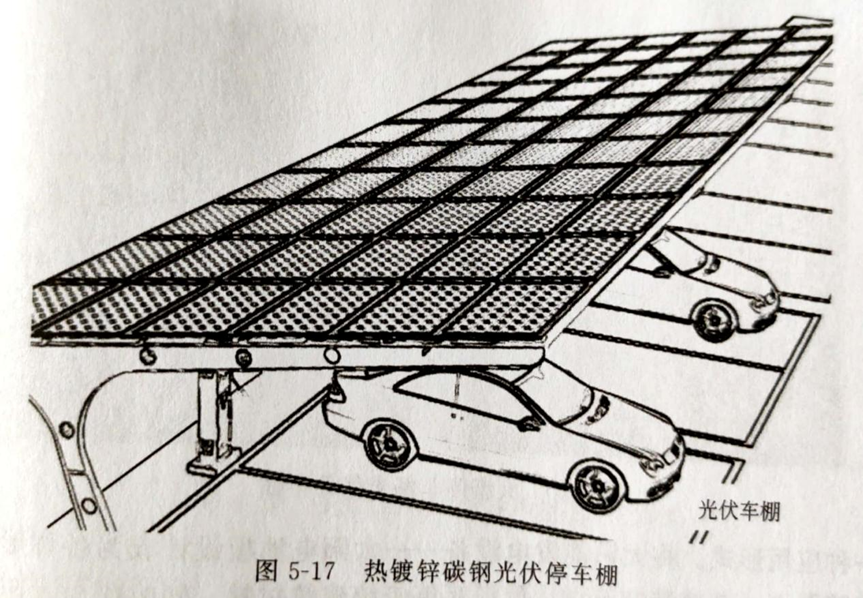

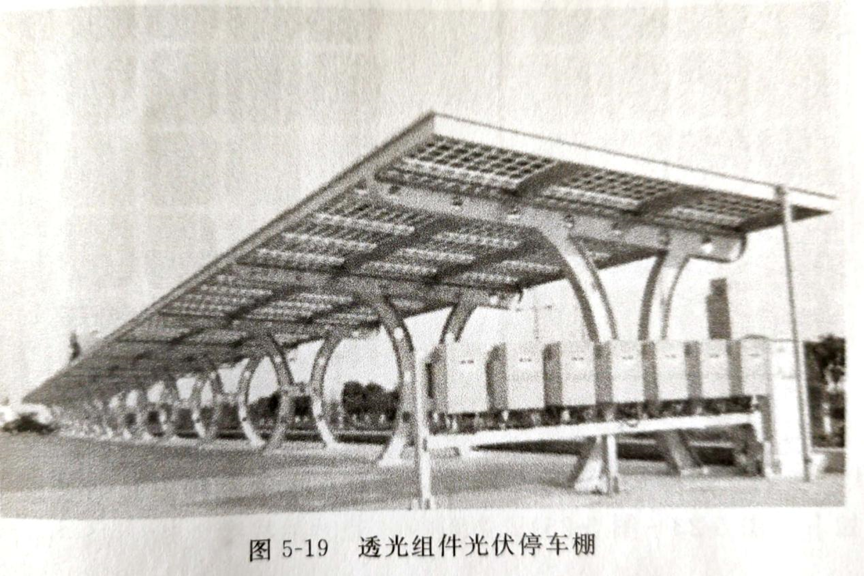

Photovoltaic parking sheds are classified into two types: hot-dip galvanized steel (as shown in Figure 5-17) and aluminum alloy profiles (as shown in Figure 5-18). According to the number of photovoltaic array slopes, photovoltaic carports can be divided into single-slope and double-slope forms. Photovoltaic carports can be divided into ordinary photovoltaic carports and light-transmitting BIPV photovoltaic carports depending on the type of components selected (Figure 5-19). The distance between the left and right columns of the photovoltaic carport is generally a span of two parking spaces. Some of the foundations of photovoltaic carports are underground, and there are also strip foundations on the ground. The gap of photovoltaic parking shed components can be designed in a conventional way, without waterproof design and measures. The gap between the photovoltaic modules can also be designed to be waterproof, so that the photovoltaic parking shed can achieve the waterproof effect as a whole. Figure 5-20 shows the photovoltaic parking shed in a large parking lot.

(4)停车棚光伏安装形式

光伏车棚是将光伏发电与车棚相结合的系统。既能为车辆遮风挡雨,又能利用太阳能创造出清洁光伏能源供电动车充电、灯光照明和并入电网。此系统建造几乎没有地域限制,非常灵活方便,综合利用空间资源发展新能源。有些汽车制造的公司,厂区内有非常大的停车场,而且一些新车在停车场日晒雨淋,建造光伏停车棚既能实现分布式光伏发电,同时也为车辆停放创造更好的环境。只要有足够的场地,光伏车棚不仅能够实现绿色能源发电的收益,棚所不能有的功能,而且也满足了常规车棚所不能有的功能,而且随着不同应用技术的发展,给电动汽车充电,给电动自行车充电,也越来越现实。现在越来越多的加油站、服务区等安装分布式光伏发电停车棚和电动车充电桩。真正享受到绿色能源给生活带来的方便。

光伏停车棚根据支架材质分类主要形式分为热镀锌钢材(如图5-17)和铝合金型材(如图5-18)两种类型。根据光伏阵列坡的数量分类,光伏车棚可以分为单坡和双坡形式。光伏车棚选用组件形式的不同,可以分为普通光伏车棚和透光BIPV光伏车棚(图5-19)。光伏车棚左右立柱间距一般以两个车位一个跨度。光伏车棚的基础有些在地下,也有在地上的条形基础。光伏停车棚组件间隙可以按常规方式设计,不做防水设计和措施。光伏组件之间的间隙也可以做防水设计,使光伏停车棚整体达到防水效果。图5-20为大型停车场光伏停车棚。

(5) Common BIPV photovoltaic installation forms

BIPV is an acronym for Building Integrated Photovoltaic. BIPV refers specifically to a form of application in which solar power generation systems are combined with urban buildings. The solar power generation equipment - solar panels are designed as various forms of building decoration materials, replacing traditional building materials such as glass curtain walls, exterior wall decorative stones, roof tiles, etc. At the same time, as a solar photovoltaic power generation system, it provides green and environmental protection for electricity loads. , clean electricity.

The photovoltaic curtain wall must meet the requirements of BIPV: in addition to the power generation function, it must meet all functional requirements of the curtain wall. Including external maintenance, transparency, mechanics, aesthetics, safety factors, etc., the cost of components is high, and the photovoltaic performance is low. It must be designed, constructed and installed at the same time as the building. The progress of the photovoltaic system project is restricted by the overall progress of the building; the photovoltaic array deviates from the optimum The installation angle, the output power is low; the cost of power generation is high; it enhances the social value of the building and brings the effect of the "green" concept.

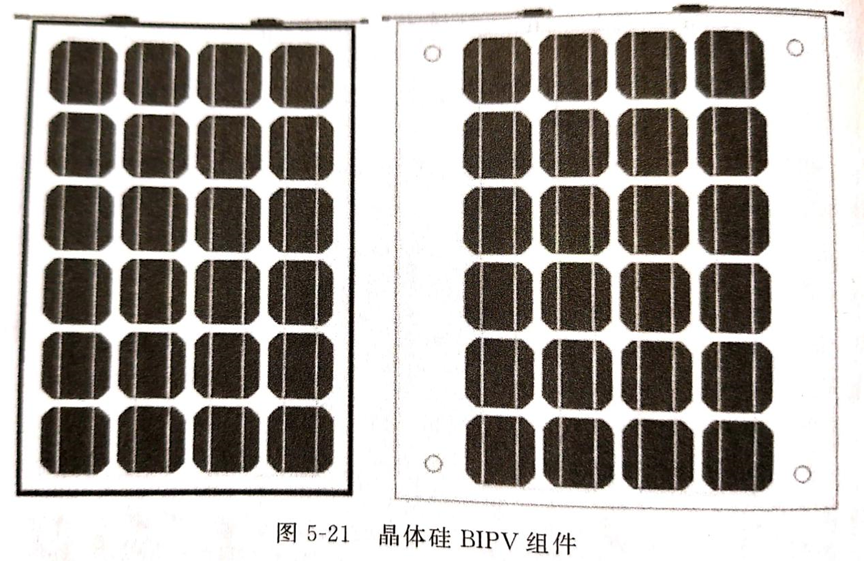

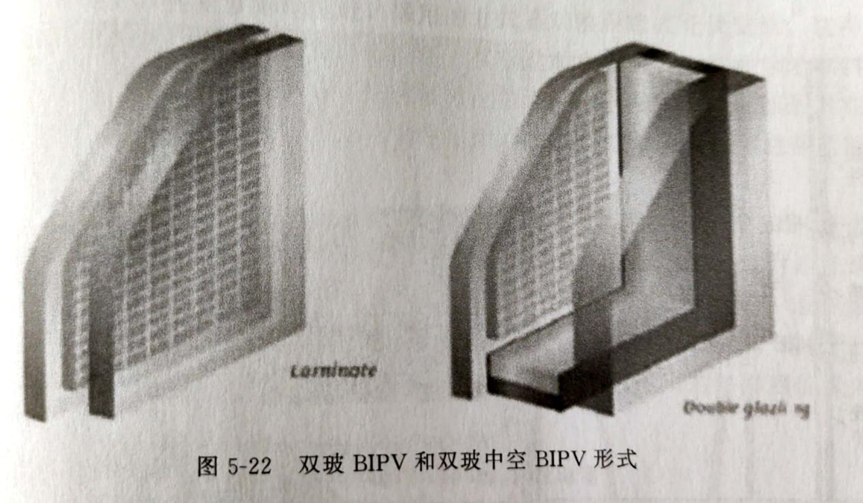

BIPV photovoltaic modules are divided into crystalline silicon BIPV and thin film BIPV modules. According to the different installation forms, there are purlin installation and point support installation forms (as shown in Figure 5-21). According to different architectural design requirements, photovoltaic BIPV modules are divided into two types. Glass-laminated modules and hollow LOW-E photovoltaic modules (as shown in Figure 5-22), the size of the glass layout and the transmittance of the cells also need to be customized by the manufacturer according to the architectural design requirements, and the thickness of the glass should also be based on the layout. The size is designed by the manufacturer. Most of the junction boxes of BIPV photovoltaic modules are on the side, which is convenient for the concealment and convenience of wiring during installation.

(5)常见 BIPV 光伏安装形式

BIPV是 Building Integrated Photovoltaic的缩写。BIPV 特指太阳能发电系统与城市建筑相结合的一种应用形式。将太阳能发电设备——太阳电池板设计成为各种形式的建筑装饰材料,取代玻璃幕墙、外墙装饰石材、屋顶瓦等传统建筑材料,同时作为太阳能光伏发电系统,为用电负载提供绿色、环保、清洁的电力。

光伏幕墙要符合BIPV 要求:除发电功能外,要满足幕墙所有功能要求。包括外部维护、透明度、力学、美学、安全因素等,组件成本高,光伏性能偏低,要与建筑物同时设计、同时施工和安装,光伏系统工程进度受建筑总体进度制约;光伏阵列偏离最佳安装角度,输出功率偏低;发电成本高;为建筑提升社会价值,带来“绿色”概念的效果。

BIPV光伏组件分为晶体硅 BIPV和薄膜BIPV组件,根据安装形式的不同,有檩条安装和点支撑安装形式(如图5-21所示),根据建筑设计要求的不同,光伏 BIPV组件分为双玻夹胶组件和中空LOW-E光伏组件(如图5-22所示),玻璃版面的大小和电池片的透光率也需要厂家根据建筑设计要求进行定制,玻璃的厚度也要根据版面的大小由厂家进行设计。BIPV光伏组件的接线盒大部分在侧面,便于安装时走线的隐蔽和便利性。

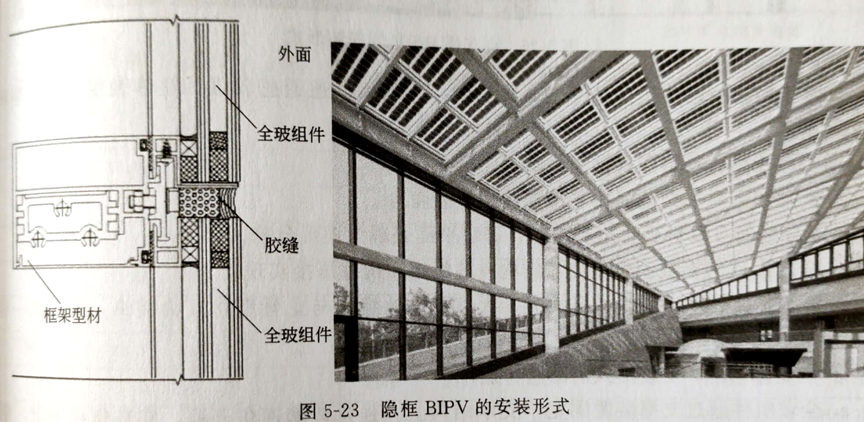

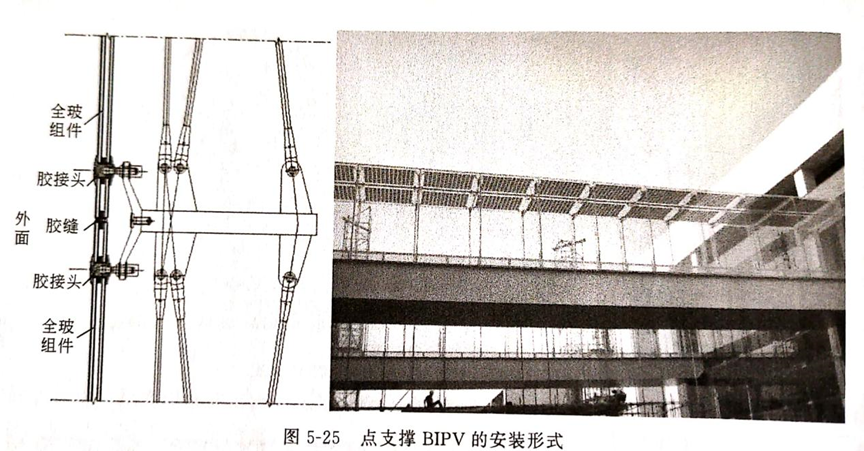

The installation forms of BIPV photovoltaic curtain wall include hidden frame, exposed frame and point support. The characteristics and schematic diagrams of different installation forms are as follows (Figure 5-23~Figure 5-25).

BIPV光伏幕墙的安装形式有隐框、明框以及点支撑等几种安装形式,不同的安装形式的特点及示意图如下(图5-23~图5-25)。

①Structural features of hidden frame BIPV installation form

a. The horizontal and vertical frames are not exposed on the outer surface of the curtain wall glass. Bone lattice and window frame cannot be seen between the glass compartments, only glued or installed.

b. The installation and fixation of all-glass components is mainly realized by the bonding of structural adhesives.

c. The curtain wall as a whole shows a beautiful plane, the appearance is unified and novel, the sense of transparency is strong, and the overall expression is a simple and lively style.

③ Structural characteristics of point support BIPV installation form

a, The full glass module is fixed on the supporting structure by the supporting device. The four corners of the tempered glass are opened and fixed with bolts. The bolts are flush with the surface of the glass, so that the inside and outside can be circulated and integrated.

b. The installation and fixation of all-glass components is mainly fixed on the connecting parts of the supporting structure, and the all-glass components are bonded by structural adhesive.

c. There is no frame structure, only simple structures such as tie rods and ropes. The interior is bright and open, with a strong sense of transparency. It is suitable for large buildings and building lobby tops or populations.

①隐框BIPV安装形式的结构特点

a.横向和竖向框架不显露于幕墙玻璃外表面。玻璃分格间看不到骨格和窗框,仅可见打胶胶逢或安装逢。

b.全玻组件的安装固定主要靠结构胶的粘接实现。

c.幕墙整体表现出美观的平面,外观统一、新颖,通透感较强,整体表现一种简洁明快的格调。

②明框BIPV安装形式的结构特点

a.横向和竖向框架均显露于幕墙玻璃外表面。

玻璃分格间可以看到骨格和窗框,幕墙平面表现为矩形分格。

b.全玻组件的安装固定主要靠结构胶的粘接和构件压接实现。

c.幕墙整体表现出明显的层次感,太阳能电池组件与龙骨型材互为装饰,表现出一种建筑美学。

③点支撑BIPV安装形式的结构特点

a,全玻组件通过支撑装置固定于支承结构上。强化玻璃四角开孔,穿装螺栓固定,螺栓与玻璃表面平齐,使内外流通、融合。

b.全玻组件的安装固定主要固定于支承结构的驳接件穿装,全玻组件间通过结构胶粘接完成。

c.没有框架结构,只有拉杆、绳索等简单结构,室内明亮开阔,通透感极强适用于大型建筑和建筑物的大堂顶部或人口等。