-

1.1前 言

-

1.2目录

-

1.3Chapter 1 Introduction to New Energy Vehicles

-

1.3.11.1 Environmental Impact

-

1.3.1.11.1.1 Air Pollution

-

1.3.1.21.1.2 Global Warming

-

1.3.1.31.1.3 Petroleum Resources

-

1.3.21.2 Sustainable Transportation

-

1.3.31.3 EV History

-

1.3.3.11.3.1 The Early Years

-

1.3.3.21.3.2 1970s

-

1.3.3.31.3.3 1980s and 1990s

-

1.3.3.41.3.4 EV Market

-

1.3.41.4 History of HEVs

-

1.3.51.5 History of Fuel Cell Vehicles

-

1.4Chapter 2 New Energy Vehicle Types

-

1.4.12.1 Electric Vehicles

-

1.4.1.12.1.1 Configuration of Electric Vehicles

-

1.4.1.22.1.2 Conceptual Illustration of a General EV Conf...

-

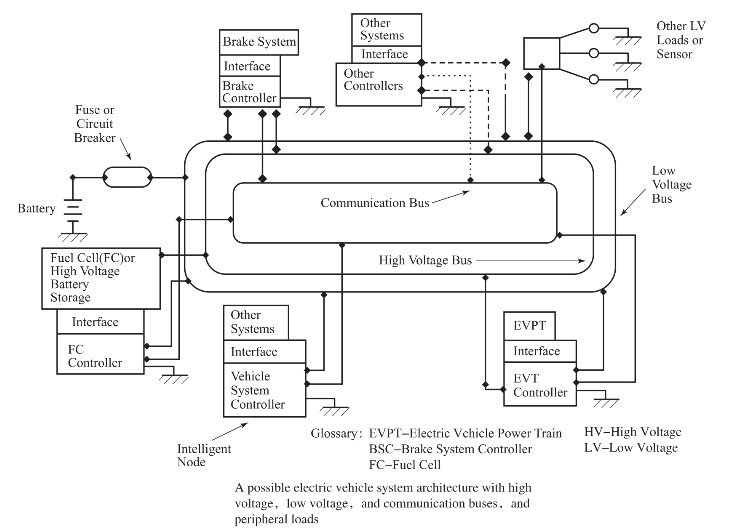

1.4.1.32.1.3 System Level Diagram of an EV

-

1.4.22.2 Hybrid Electric Vehicles

-

1.4.2.12.2.1 Parallel Hybrid

-

1.4.2.22.2.2 Series Hybrid

-

1.4.2.32.2.3 Series-parallel Hybrid

-

1.4.2.42.2.4 Complex Hybrid

-

1.4.32.3 Plug-in Hybrid Electric Vehicle(PHEV)

-

1.4.3.12.3.1 Why PHEV

-

1.4.3.22.3.2 Constituents of a PHEV

-

1.4.42.4 Fuel Cell Vehicles(FCVs)

-

1.5Chapter 3 Energy Storages

-

1.5.13.1 Electrochemical Batteries

-

1.5.23.2 Battery Characterization

-

1.5.33.3 Battery Technologies

-

1.5.3.13.3.1 Lead-Acid Battery

-

1.5.3.23.3.2 Nickel-Based Batteries

-

1.5.3.33.3.3 Lithium-Based Batteries

-

1.5.43.4 Supercapacitors and Ultracapacitors

-

1.5.53.5 Flywheels

-

1.5.63.6 Fuel Cells

-

1.5.6.13.6.1 Operating Principles of Fuel Cells

-

1.5.6.23.6.2 Fuel Cell Technologies

-

1.6Chapter 4 Management of Energy Storage Systems

-

1.6.14.1 Introduction

-

1.6.24.2 Battery Management

-

1.6.2.14.2.1 Parameter Monitoring

-

1.6.2.24.2.2 Calculation of SOC

-

1.6.2.34.2.3 Fault and Safety Protection

-

1.6.2.44.2.4 Charge Management

-

1.6.34.3 Battery Cell Balancing

-

1.7Chapter 5 Electric Propulsion Systems

-

1.7.15.1 Electric Motors

-

1.7.1.15.1.1 Advantage of Electric Motors

-

1.7.1.25.1.2 Classification of Electric Motors

-

1.7.25.2 Electronic Structure

-

1.7.35.3 Electronic Converters

-

1.7.3.15.3.1 Components of Electronic Converters

-

1.7.3.25.3.2 Rectifiers

-

1.7.3.35.3.3 Choppers

-

1.7.3.45.3.4 Inverters

-

1.8Chapter 6 Recharging Systems for Electric Vehicles

-

1.8.16.1 What Is Battery Charging

-

1.8.26.2 The Various Types of Chargers

-

1.8.36.3 Recharging Efficiency

-

1.8.46.4 Recharging in Complete Safety

-

1.8.56.5 Charging Methods

-

1.8.5.16.5.1 Constant Voltage Charge

-

1.8.5.26.5.2 Constant Current Charge

-

1.8.5.36.5.3 Taper Current Charge

-

1.8.5.46.5.4 Pulse Charge

-

1.8.5.56.5.5 Reflex Charge

-

1.8.5.66.5.6 Float Charge

-

1.8.66.6 Termination Methods

-

1.8.6.16.6.1 Time

-

1.8.6.26.6.2 Voltage

-

1.8.6.36.6.3 Voltage Drop(dV/dT)

-

1.8.6.46.6.4 Current

-

1.8.6.56.6.5 Temperature

-

1.9第1章 新能源汽车概述

-

1.9.11.1 环境影响

-

1.9.1.11.1.1 大气污染

-

1.9.1.21.1.2 全球变暖

-

1.9.1.31.1.3 石油资源

-

1.9.21.2 可持续发展的交通运输

-

1.9.31.3 电动汽车的发展史

-

1.9.3.11.3.1 早期

-

1.9.3.21.3.2 20世纪70年代

-

1.9.3.31.3.3 20世纪80年代和90年代

-

1.9.3.41.3.4 电动汽车的市场前景

-

1.9.41.4 混合动力电动汽车的历史

-

1.9.51.5 燃料电池电动汽车的历史

-

1.10第2章 新能源汽车类型

-

1.10.12.1 纯电动汽车

-

1.10.1.12.1.1 纯电动汽车结构

-

1.10.1.22.1.2 EV结构的概念性图示

-

1.10.1.32.1.3 EV系统级原理图

-

1.10.22.2 混合动力电动汽车

-

1.10.2.12.2.1 并联式混合

-

1.10.2.22.2.2 串联式混合

-

1.10.2.32.2.3 混联式混合

-

1.10.2.42.2.4 复联式混合

-

1.10.32.3 插电式混合动力电动汽车

-

1.10.3.12.3.1 为什么需要插电式混合动力电动汽车

-

1.10.3.22.3.2 插电式混合动力电动汽车的结构

-

1.10.42.4 燃料电池电动汽车

-

1.11第3章 能量储存装置

-

1.11.13.1 电化学蓄电池组

-

1.11.23.2 电池特性参数

-

1.11.33.3 蓄电池技术

-

1.11.3.13.3.1 铅酸蓄电池

-

1.11.3.23.3.2 镍基蓄电池

-

1.11.3.33.3.3 锂基蓄电池

-

1.11.43.4 超大容量电容器和超级电容器

-

1.11.53.5 飞 轮

-

1.11.63.6 燃料电池

-

1.11.6.13.6.1 燃料电池的工作原理

-

1.11.6.23.6.2 燃料电池技术

-

1.12第4章 储能系统的管理

-

1.12.14.1 简 介

-

1.12.24.2 电池管理

-

1.12.2.14.2.1 参数监测

-

1.12.2.24.2.2 SOC的计算

-

1.12.2.34.2.3 故障和安全保护

-

1.12.2.44.2.4 充电管理

-

1.12.34.3 电池单体均衡

-

1.13第5章 电驱动系统

-

1.13.15.1 电动机

-

1.13.1.15.1.1 电动机应用优势

-

1.13.1.25.1.2 电动机的分类

-

1.13.25.2 电气结构

-

1.13.35.3 功率电子变换器

-

1.13.3.15.3.1 功率电子元件

-

1.13.3.25.3.2 整流器

-

1.13.3.35.3.3 斩波器

-

1.13.3.45.3.4 逆变器

-

1.14第6章 电动汽车的充电系统

-

1.14.16.1 什么是电池的充电

-

1.14.26.2 不同类型的充电器

-

1.14.36.3 充电效率

-

1.14.46.4 充电的安全问题

-

1.14.56.5 电池的充电方式

-

1.14.5.16.5.1 恒压充电

-

1.14.5.26.5.2 恒流充电

-

1.14.5.36.5.3 锥电流充电

-

1.14.5.46.5.4 脉冲充电

-

1.14.5.56.5.5 反射充电

-

1.14.5.66.5.6 浮压充电

-

1.14.66.6 充电的终止方式

-

1.14.6.16.6.1 时间

-

1.14.6.26.6.2 电压

-

1.14.6.36.6.3 电压降(dV/dT)

-

1.14.6.46.6.4 电流

-

1.14.6.56.6.5 温度

-

1.15参考文献

1

新能源汽车专业英语