Types of Brakes

Two types of brakes are used in modern cars: drum brakes and disc brakes. Since 1976, all cars have used disc brakes on the front wheels. Most cars use drum brakes on the rear wheels . In both drum and disc brakes, a hydraulic system applies the brakes. The hydraulic system connects the brake pedal to the brake parts at each wheel.

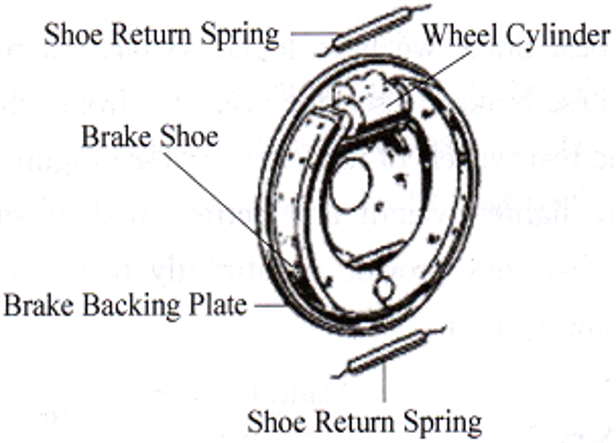

1 Drum brake

Drum brakes have two shoes. anchored to a stationary back-plate, which are internally expanded to contact the drum by hydraulic cylinders or a mechanical linkage (FIg. 4-2)

A leading shoe may be defined as one where the direction of drum rotation is from the applied load end or toe to the fulcrum end or heel. Conversely, a trailing shoe is one where the direction of drum rotation over its liner is from the heel to the toe. The significance of leading and trailing shoes is that they are self-energizing and non-self-energizing respectively. That is, a leading shoe will generate a greater braking drag force on the drum than a trailing shoe for the same applied load at their toes. On the other hand, a leading shoe is more sensitive to variations in friction level with heating and thus tends to be less stable in operation than a trailing shoe.

Different drum brake designs result from considerations with regard to application, support and adjustment of the brake shoes. brakes are assessed in terms of the brake factor C"\ which expresses the ratio of longitudinal to tensioning force at the brake shoe. The brake factor takes into consideration the effect the of and the interal transmission ratio of the brake.

1) Simplex Drum Brakes

There are different types of simplex drum brakes, primarily depending upon the type of application (floating, fixed) and the type of support (rotating shoes, sliding shoes) . Wheel brakes with floating brake applcaton and rotating-shoe support, for example, are common. In case of hydraulic brake force acmuaton, the brakes are applied by means of floating pressure pistons whose travel is not fixed, and develop tensioning forces which are equal in both directions. One of the two shoes is the leading shoe, . e. the frictional foreces between the brake lining the brake drum act to support the application force, whereas the frictional forees in the cases of the trailing shoe act to oppose the tensioning force.

In the case of the simplex brake, "C" is the sum of the values for the individual shoes, and is≈2.0 (referred to a special coeficient of friction). A disadvantage of this design is the great difference in the brake effect between the two brake shoes, and the resulting greatly increased wear on the leading shoe. For this reason, the trailing shoe is often equipped with a much thinner lining than the lead ing shoe.

A simplex drum brake can also be actuated by means of wedge unit, a design which is being used more and more often in light-duty commercial vehicles.

The type of wheel brake used most often in heavy-duty commercial vehicles is the pneumatic S-cam simplex drum brake with fixed application

Advantages of the S-cam brake: Uniform lining wear on leading and trailing shoes as a result of application, and resulting long lining life. This type of drum brake has an application mechanism which is simpler, more reliable and insensitive to temperature. It comprises diaphragm cylinder, automatic slack adjuster, brake shaft and S-cam.

Disadvantages of the S-cam brake: High internal forces, and thus relatively heavy brake construction because unequal cam forces occur and lead to high free bearing forces. A relatively low brake factor which results in a correspondingly large amount of application work during barking. Due to the roughly equivalent application travel of leading and trailing shoes, the application forces behave the opposite of the brake factors of the individual shoes. In general, the brake factor of this brake with the same coefficient of friction is somewhat lower than that of the above-mentioned simplex break.

2. Duo-duplex Drum Brakes

The duo-duplex dnum brake (, with wedge type actuator) has two leading shoes .This type of drum brake is used on medium and heavy-duty trucks.

This type of drum brake is characterized by floating application and the corresponding necessary sliding shoe support. The brake adjustment mechanism is an integral part of the wedge units. An advantage of this type of brake is the nearly equal brake lining wear on both shoes and the higher internal transmission ratio in comparison to simplex brakes. With two leading shoes, brake factors of C≈3. are achieved, however these figures cannot be held constant throughout a long period of brake due to the susceptibility to fading of this type of brake.

3. Duo-servo Drum Brakes

Duo-servo drum brakes are widely used in light-duty commercial vehicles ( particularly at the rear axles) . They are characterized primarily by the fact that the support force of the primary shoe is used as the tensioning force for the secondary shoe both during forward and reverse vehicle motion. The brake factor is C≈5.0.

The reason for the popularity of the duo-servo brake is that the high brake factors allow even relatively heavy vans and light-duty trucks up to a weight of approx. 7.5t to be operated with a vacuumassisted braking system. At the same time, the integral manually operated parking brake is able to generate a brake torque of considerable magnitude. Significant fluctuations in the brake factor occur however, thus limiting the range of application of this type of drum brake and making necessary a sys tem of brake force apportioning which is well matched to the vehicle in question.

2 Disc Brakes

Exposed to the air, disc brakes radiate the heat to the air better than drum brakes: This means that the brake can operated continuously for a longer period, i. e. they have a greater resistance to fade (fall-off in brake efficieney due to heat).

Disc brakes as used in most passenger cars are slowly beginning to be used in commercial vehicles as well. Aside from their use fast coaches, current use of disc brakes in commercial vehicles is primarily limited to frontaxie brakes or commercial vehicles up to a weight of appra. 7. 5t which are driven in a manner similat to passenger cars.

Advantages over drum brakes: much better gradual braking efficiency; equal wear of the inboard and outboard brake pads if the proper degree of heat dissipation is provided: brake noise is better suppressed; relatively constant brake factor performance with lower susceptibility to fading.

Disadvantages over drum brakes: possible short brake pad life when used on heavy-duty commercial vehicles, and higher acquisition and operating costs as compared to drum brakes. The high degree of adaptive braking at high highway speeds is generally handled better by disc brakes with less fading and lower suscep tibility to disc cracking than with drum brakes. The brake factor is C≈7.5.

Floating-caliper disc brakes continue to replace the fixed-caliper brakes generally used to date. This tendency has resulted from efforts to design lighter and cheaper brake assemblies which are more temperature-resistant. The caliper itself is not subjected to braking torque, and thus promotes gradual and constant brake action.