Steering System

1 Basic parts of steering system

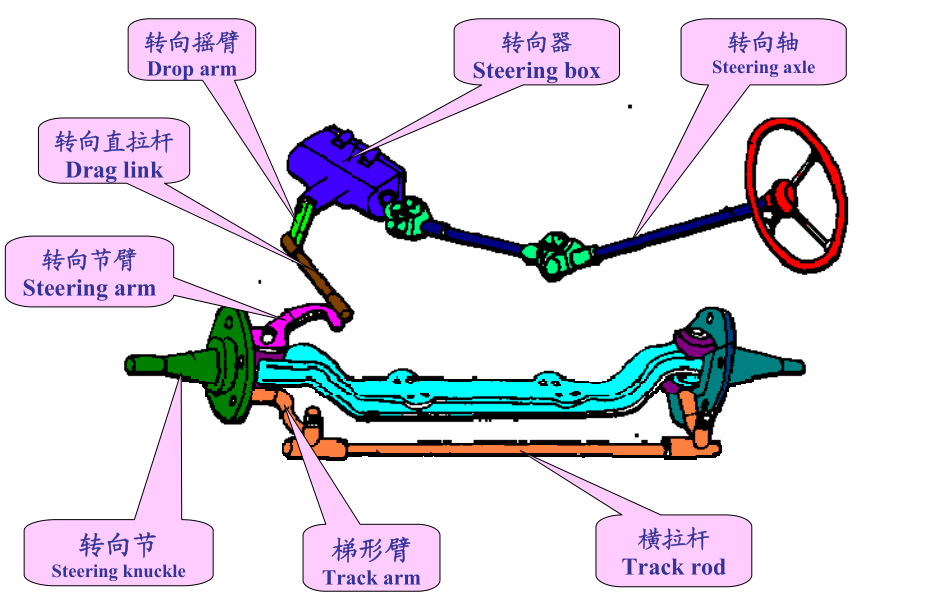

The steering converts the steering-wheel rotary motion into a turn motion of the steered wheels of the vehicle.The basic steering system in most cars is the same. The steering gear of steering box is the heart of the steering system. This usually is next to the engine. A shaft extends from the back of the steering gear. This shaft is connected to the steering column or steering shaft. The steering wheel is at the top of the steering column. Another shaft comes from the bottom of the steering gear. This shaft connects to the arms, rods, and links. This parts assembly, called the steering linkage,connects the steering gear to the parts at the wheels. The wheels and tires mount to the steering knuckles. As shown in Fig. 5-1, the knuckles are pivoted at the top and bottom. Thus, the wheels and tires can turn from side to side.

While the steering system may look complicated, it works quite simply. When a driver drives a car straight down the road, the steering gear is centered. The gear holds the linkage centered so that the wheels and tires point straight ahead. When the driver turns the steering wheel, the steering shaft rotates and the steering gear moves toward that side. The shaft coming out the bottom of the steering gear turns, as well. When the shaft turns, it pulls the linkage to one side and makes the steering knuckles turn slightly about their pivot points. Thus, the steering knuckle, spindle, wheels, and tires turn to one side, causing the car to turn.

The type of steering layout depends on the suspension system. The beam axle used on he commercial vehicles has a king pin fitted at each end of the axle and this pin is the pivot which allows the wheels to be steered . Cars have independent suspension and this system h ball joints to allow for wheel movement.

2 Requirements on Steering System

The steering system must guarantee easy and safe steering of the vehicle :it must be possible to turn the front wheels into the position corresponding to a turning circle with a radius of 12m within a maximum of 6s. if such power assistance fails, 600N must not exceeded. The actuating force must be hamonious from the center as far as the end stop and must not decrease. It must be possible to the vehicle accurately, i. e. without any unusual steering corrections.

The entirety of the mechanical transmission devices must be able to cope with all loads and stresses occurring in operation. Unusual driving maneuvers. such as driving over obstacles, accident-like occurrences etc. , must not lead to any cracks or breakages.

The requirements in terms of steering behavior can be summarized as follows:

1) Jolts from irregularities in the road surface must be damped as much as possible in being to the steering wheel. However, such damping must not cause the driver to lose contact the road.

2) The basic design of the steering kinematics must satisfy the Ackermann conditions: the ex tensions of the wheel axes of the left and right front wheels, when at an angle, intersect on an extension of the rear axle.

3) By means of suitable stiffness of the steering system( particularly if rubber-elastic connections are used) the vehicle must react to minute steering corrections.

4) When the steering wheel is released, the wheels must return automatically to the straight-ahead position and must remain stable in this position.

5) The steering should have as low a ratio as possible (number of steering-wheel turns from ) in order to obtain ease of handling. The thereby occurring steering forces are determined not by the steering ratio, but also by the front-axle loading, the size of the turning circle, the eel suspension (caster, steeringaxis inclination, steering roll radius) and the tire tread .