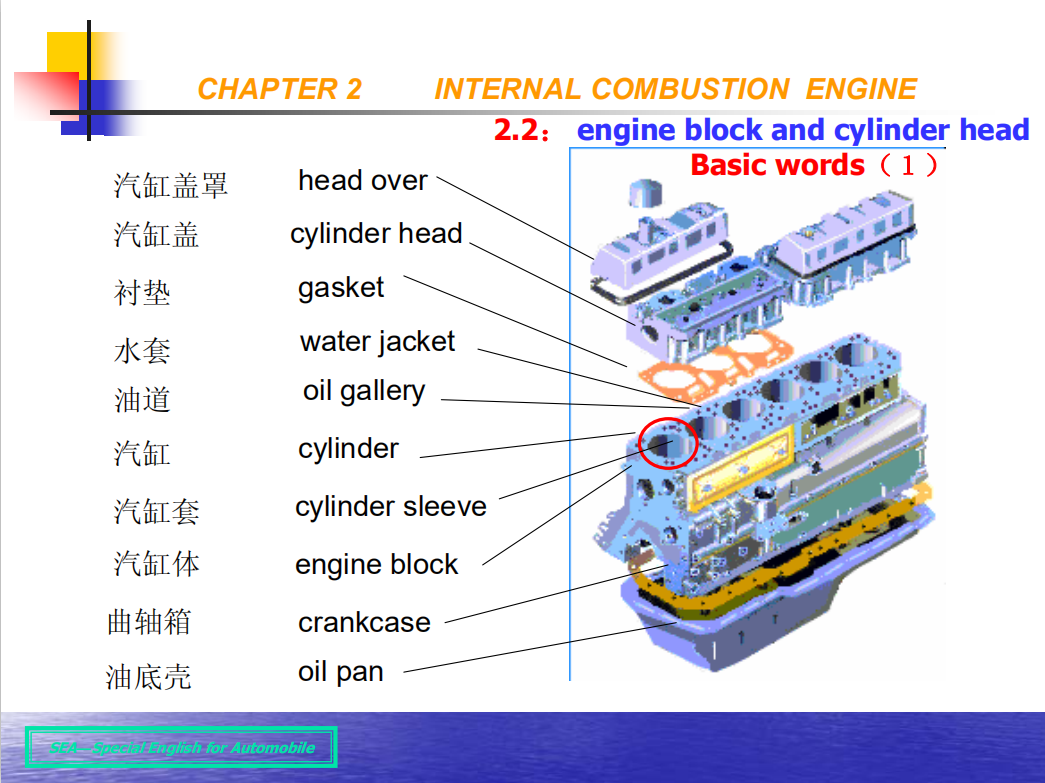

engine block and cylinder head

1 Engine block

The engine block is the basic frame of the engine. All other engine parts either fit inside it or fasten to it. It holds the cylinders, water jackets, and oil galleries. The engine block also holds the crankshaft, which fastens to the bottom of the block. The camshaft also fits inside the block, except on overhead-cam engines (OHC).

In most cars, this block is made of gray iron, or an alloy (mixture) of gray iron and other metals, such as nickel or chromium. Engine blocks are castings.

Some engine blocks, especially those in smaller cars, are made of cast aluminum. This metal is much lighter than iron. However, iron wears better than aluminum. Therefore, the cylinders in most aluminum engines are lined with iron or steel sleeves. These sleeves are called cylinder sleeves. Some engine blocks are made entirely of aluminum.

2 Cylinder sleeve:

Cylinder sleeves are used in engine blocks to provide a hard wearing material for pistons and piston rings. The block can be made of one kind of iron that is light and easy to cast while the sleeves uses another that is better able to stand up wear and tear. There are two main types of sleeves: dry and wet.The dry sleeve can be cast in or pressed into a new block or used to recondition badly worn or damaged cylinders that cannot easily be rebored. It's a pressed fit in its bore in the cylinder blocks.Its wall is about two millimeters thick.Its outer surface is in contact with the block for its full length.Its top finishes flush with the top of the block and can hardly be seen.Once in place,dry sleeves become a permanent part of the cylinder block.With a wet sleeve,the outer surface is part of the water jacket around the cylinder.It's called wet because it has coolant against its outer surface.This helps speed up heat transfer between the sleeve and coolant.The sleeve is sealed at the top to prevent coolant leaks.

3 Cylinder head:

The cylinder head fastens to the top of the block, just as a roof fits over a house. The underside forms the combustion chamber with the top of the piston. In-line engine of light vehicles have just one cylinder head for all cylinders; larger in-line engines can have two or more Just as with engine blocks, cylinder heads can be made of cast iron or aluminum alloy.a head made of aluminum alloy is lighter than if when made of cast-iron.aluminum also conducts heat away more quickly than iron.in petrol engine,the three most popular types of combustion chamber are the hemi,wedge and semi-hemi. The cylinder head carries the valves, valve springs and the rockers on the rocker shaft, this part of valve gear being worked by the pushrods. Sometimes the camshaft is fitted directly into the cylinder head and operates on the valves without rockers. This is called an overhead camshaft arrangement.

4 Gasket

The cylinder head is attached to the block with high-tensile steel studs. The joint between the block and the head must be gas-tight so that none of the burning mixture can escape. This is achieved by using cylinder head gasket. This is a sandwich gasket, i.e. a sheet of asbestos between two sheets of copper, both these materials being able to withstand the high temperature and pressures within the engine.

5 Oil Pan or Sump

The oil pan is usually formed of pressed steel. The oil pan and the lower part of the cylinder block together are called the crankcase; they enclose, or encase, the crankshaft. The oil pump in the lubricating system draws oil from the oil pan and sends it to all working parts in the engine.The oil drains off and runs down into the pan. Thus, there is constant circulation of oil between the pan and the working parts of the engine.

This unit acts as a reservoir to store the oil that is reauired bv the engine lubrication .It further serves as a vessel in which any sludge,water and metal particles in the oil can settle out,and also provides an opportunity for any entrained air to escape from the oil.

Baffle plates are normally fitted in the sump to minimize both oil surging and agitation ,the former arising from the changing motion of the car and the latter from the oil flung from the crankshaft bearings ( Fig.2-9). A screwed plug is incorporated at the lowest point in the sump for draining the oil in service.