练习:http://top.zhan.com/ielts/read/review-658-1498-1-0.html

Cork

Cork - the thick bark of the cork oak tree (Quercus suber) - is a remarkable material. It is tough, elastic, buoyant, and fire-resistant, and suitable for a wide range of purposes. It has also been used for millennia: the ancient Egyptians sealed their sarcophagi (stone coffins) with cork, while the ancient Greeks and Romans used it for anything from beehives to sandals.

And the cork oak itself is an extraordinary tree. Its bark grows up to 20cm in thickness, insulating the tree like a coat wrapped around the trunk and branches and keeping the inside at a constant 20°C all year round. Developed most probably as a defence against forest fires, the bark of the cork oak has a particular cellular structure - with about 40 million cells per cubic centimetre - that technology has never succeeded in replicating. The cells are filled with air, which is why cork is so buoyant. It also has an elasticity that means you can squash it and watch it spring back to its original size and shape when you release the pressure.

Cork oaks grow in a number of Mediterranean countries, including Portugal, Spain, Italy, Greece and Morocco. They flourish in warm, sunny climates where there is a minimum of 400 millimetres of rain per year, and not more than 800 millimetres. Like grape vines, the trees thrive in poor soil, putting down deep roots in search of moisture and nutrients.Southern Portugal’s Alentejo region meets all of these requirements, which explains why, by the early 20th century, this region had become the world’s largest producer of cork, and why today it accounts for roughly half of all cork production around the world.

Most cork forests are family-owned. Many of these family businesses, and indeed many of the trees themselves, are around 200 years old. Cork production is, above all, an exercise in patience. From the planting of a cork sapling to the first harvest takes 25 years, and a gap of approximately a decade must separate harvests from an individual tree. And for top-quality cork, it’s necessary to wait a further 15 or 20 years. You even have to wait for the right kind of summer’s day to harvest cork. If the bark is stripped on a day when it’s too cold - or when the air is damp - the tree will be damaged.

Cork harvesting is a very specialised profession. No mechanical means of stripping cork bark has been invented, so the job is done by teams of highly skilled workers. First, they make vertical cuts down the bark using small sharp axes, then lever it away in pieces as large as they can manage. The most skilful cork-strippers prise away a semi-circular husk that runs the length of the trunk from just above ground level to the first branches. It is then dried on the ground for about four months, before being taken to factories, where it is boiled to kill any insects that might remain in the cork. Over 60% of cork then goes on to be made into traditional bottle stoppers, with most of the remainder being used in the construction trade. Corkboard and cork tiles are ideal for thermal and acoustic insulation, while granules of cork are used in the manufacture of concrete.

Recent years have seen the end of the virtual monopoly of cork as the material for bottle stoppers, due to concerns about the effect it may have on the contents of the bottle. This is caused by a chemical compound called 2,4,6-trichloroanisole (TCA), which forms through the interaction of plant phenols, chlorine and mould. The tiniest concentrations - as little as three or four parts to a trillion - can spoil the taste of the product contained in the bottle. The result has been a gradual yet steady move first towards plastic stoppers and, more recently, to aluminium screw caps. These substitutes are cheaper to manufacture and, in the case of screw caps, more convenient for the user.

The classic cork stopper does have several advantages, however. Firstly, its traditional image is more in keeping with that of the type of high quality goods with which it has long been associated. Secondly - and very importantly - cork is a sustainable product that can be recycled without difficulty. Moreover, cork forests are a resource which support local biodiversity, and prevent desertification in the regions where they are planted. So, given the current concerns about environmental issues, the future of this ancient material once again looks promising.

Question 1-5

Do the following statements agree with the information given in Reading Passage 1?

In boxes 1 - 5 on your answer sheet, write

TRUE if the statement agrees with the information

FALSE if the statement contradicts the information

NOT GIVEN if there is no information on this

1.The cork oak has the thickest bark of any living tree.

2.Scientists have developed a synthetic cork with the same cellular structure as natural cork.

3.Individual cork oak trees must be left for 25 years between the first and second harvest.

4.Cork bark should be stripped in dry atmospheric conditions.

5.The only way to remove the bark from cork oak trees is by hand.

6. 图表题(表格题+流程图题)

特点分析:变形的简答题;立体的填空题;没有选项的单选题;答案密集出现(集中在某个段落里出现),且遵循顺序原则,即答案按顺序出现/行文顺序和出题顺序一致;正确答案为原文原词,属于送分题(找到定位区间就能拿分)

解题:

分析图表题类别,确定是表格还是流程图还是其他

如果是流程图先确认事物/事件类别,然后回原文定位;如果是表格先确认找寻类别再回原文定位

将图表题下小题看做连续的填空题,找寻关键词帮助缩小定位空间,其中流程图应先关注第一空定位区间

注意题目对答题字数限制要求,摘取原文原词进行填空

例子:http://top.zhan.com/ielts/read/review-135-282-1-0.html

How a Sixteenth-Century Warship Was Recovered From the Seabed

On 19 July 1545, English and French fleets were engaged in a sea battle off the coast of southern England in the area of water called the Solent, between Portsmouth and the Isle of Wight. Among the English vessels was a warship by the name of Mary Rose. Built in Portsmouth some 35 years earlier, she had had a long and successful fighting career, and was a favourite of King Henry VIII. Accounts of what happened to the ship vary: while witnesses agree that she was not hit by the French, some maintain that she was outdated, overladen and sailing too low in the water, others that she was mishandled by undisciplined crew. What is undisputed, however, is that the Mary Rose sank into the Solent that day, taking at least 500 men with her. After the battle, attempts were made to recover the ship, but these failed.

The Mary Rose came to rest on the seabed, lying on her starboard (right) side at an angle of approximately 60 degrees. The hull (the body of the ship) acted as a trap for the sand and mud carried by Solent currents. As a result, the starboard side filled rapidly, leaving the exposed port (left) side to be eroded by marine organisms and mechanical degradation. Because of the way the ship sank, nearly all of the starboard half survived intact. During the seventeenth and eighteenth centuries, the entire site became covered with a layer of hard grey clay, which minimised further erosion.

Then, on 16 June 1836, some fishermen in the Solent found that their equipment was caught on an underwater obstruction, which turned out to be the Mary Rose. Diver John Deane happened to be exploring another sunken ship nearby, and the fishermen approached him, asking him to free their gear. Deane dived down, and found the equipment caught on a timber protruding slightly from the seabed. Exploring further, he uncovered several other timbers and a bronze gun. Deane continued diving on the site intermittently until 1840, recovering several more guns, two bows, various timbers, part of a pump and various other small finds.

The Mary Rose then faded into obscurity for another hundred years. But in 1965, military historian and amateur diver Alexander McKee, in conjunction with the British Sub-Aqua Club, initiated a project called 'Solent Ships'. While on paper this was a plan to examine a number of known wrecks in the Solent, what McKee really hoped for was to find the Mary Rose. Ordinary search techniques proved unsatisfactory, so McKee entered into collaboration with Harold E. Edgerton, professor of electrical engineering at the Massachusetts Institute of Technology. In 1967, Edgerton's side-scan sonar systems revealed a large, unusually shaped object, which McKee believed was the Mary Rose.

Further excavations revealed stray pieces of timber and an iron gun. But the climax to the operation came when, on 5 May 1971, part of the ship's frame was uncovered. McKee and his team now knew for certain that they had found the wreck, but were as yet unaware that it also housed a treasure trove of beautifully preserved artefacts. Interest in the project grew, and in 1979, The Mary Rose Trust was formed, with Prince Charles as its President and Dr Margaret Rule its Archaeological Director. The decision whether or not to salvage the wreck was not an easy one, although an excavation in 1978 had shown that it might be possible to raise the hull. While the original aim was to raise the hull if at all feasible, the operation was not given the go-ahead until January 1982, when all the necessary information was available.

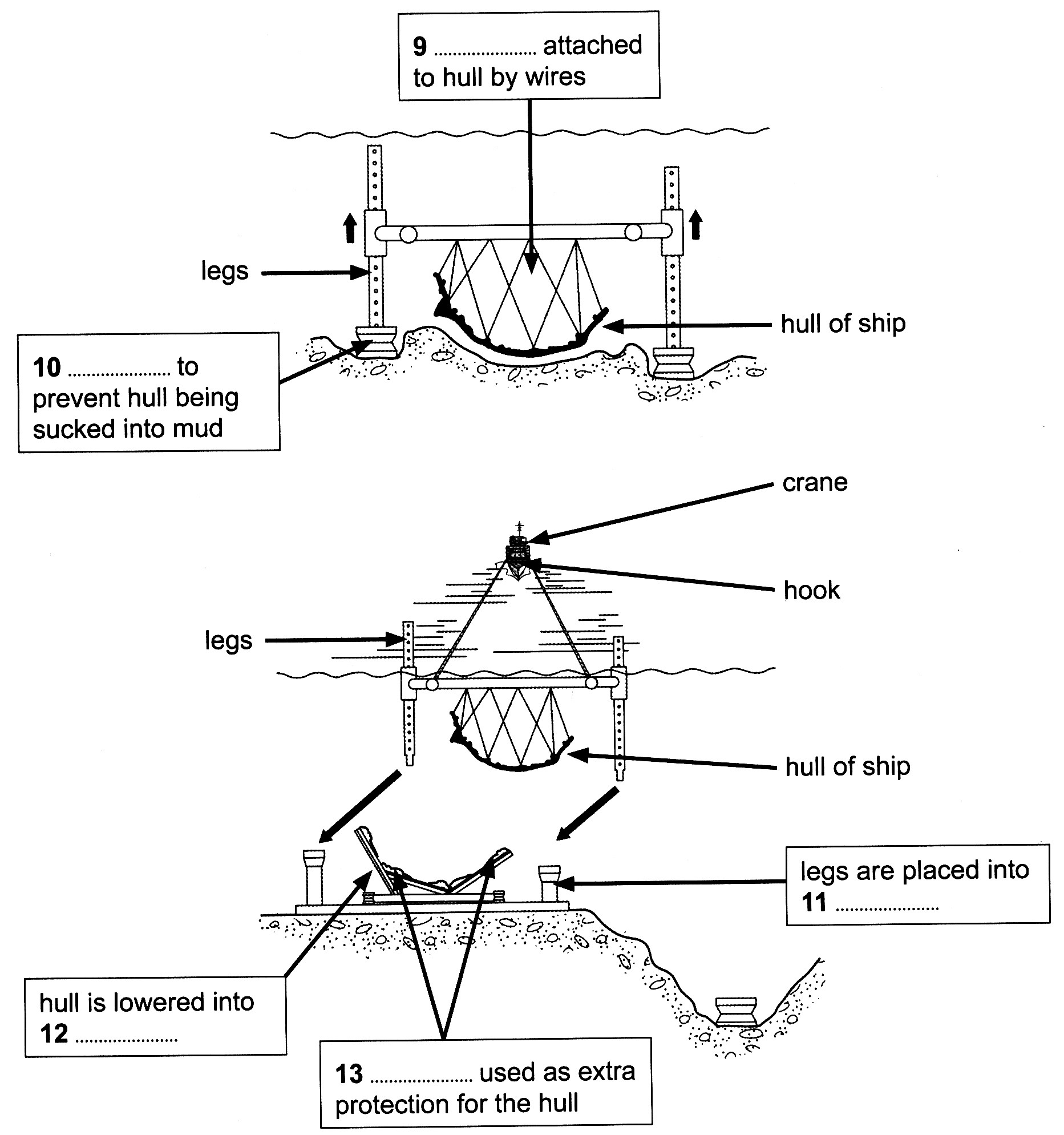

An important factor in trying to salvage the Mary Rose was that the remaining hull was an open shell. This led to an important decision being taken: namely to carry out the lifting operation in three very distinct stages. The hull was attached to a lifting frame via a network of bolts and lifting wires. The problem of the hull being sucked back downwards into the mud was overcome by using 12 hydraulic jacks. These raised it a few centimetres over a period of several days, as the lifting frame rose slowly up its four legs. It was only when the hull was hanging freely from the lifting frame, clear of the seabed and the suction effect of the surrounding mud, that the salvage operation progressed to the second stage. In this stage, the lifting frame was fixed to a hook attached to a crane, and the hull was lifted completely clear of the seabed and transferred underwater into the lifting cradle. This required precise positioning to locate the legs into the 'stabbing guides' of the lifting cradle. The lifting cradle was designed to fit the hull using archaeological survey drawings, and was fitted with air bags to provide additional cushioning for the hull's delicate timber framework. The third and final stage was to lift the entire structure into the air, by which time the hull was also supported from below. Finally, on 11 October 1982, millions of people around the world held their breath as the timber skeleton of the Mary Rose was lifted clear of the water, ready to be returned home to Portsmouth.

Question 9-13

Label the diagram below.

Choose NO MORE THAN TWO WORDS from the passage for each answer.

Write your answers in boxes 9-13 on your answer sheet.

9. ______________

10.______________

11.______________

12.______________

13. ______________