In this chapter, we willstudy the manufacturing from a system point of view as shown in the following figure.

Computer integrated manufacturing(CIM) is a broad term covering all technologies and soft automation used to manage the resources for cost effective production of tangible goods. This integration allows individual processes to exchange information with each other and initiate actions. Through the integration of capital, human, technology and equipment under computer hardware and software control, manufacturing can be faster and less error-prone,although the main advantage is the ability to create automated manufacturing processes.

CIM system functional areas such as design, analysis, planning, purchasing, cost accounting,inventory control, and distribution are linked through the computer with factory floor such as materials handling and management, providing direct control and monitoring of all the operations.

Chapter 5 will introduce principles and theories of Computer Integrated Manufacturing System (CIMS), especiallyfocus on the subsystem FMS (Flexible Manufacturing System). Other technologies, such as lean manufacturing and just in time will also be discussed.

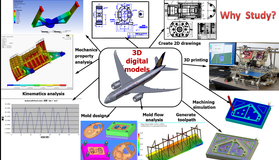

The general stages in CIMS are as follows:

Flow chart of main stages in CIMS