Chapter 10 Logistics Information Technology

10.4 Order Management and Customer Service through Information System

10.4.1 Information enabler in management

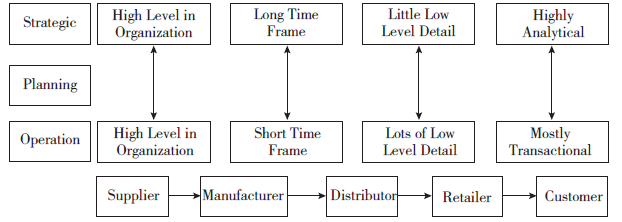

Information system plays an important role in every stage of the supply chain by enabling companies to collect and analyze information. Information Technology(IT)levels of functionality in the supply chain management are illustrated in Figure 10.1.

Figure 10.1 IT levels of functionality in the supply chain management

As shown in Figure 10.1, IT systems can be used to make strategic, planning, or operational

decisions within a supply chain.

1.Strategic decisions

Strategic decisions involve a long-time frame(e.g., 10 years)in which decisionmakers must determine what products to make, how many facilities to build, where they should be located, what type of distribution system to have, what functions to implement in house or outsource, and what type of demand to target. The information needed for this level tends to be very broad rather than detailed. IT systems used at this level are highly analytical since they concentrate on analyzing rather than collecting information. Strategic IT tools are targeted toward people at a higher level in the company.

2. Planning decisions

It usually takes several months or one year to make planning decisions. The objective of planning decisions is to allocate available resources to best meet anticipated demanda. Managers must determine the approximate amounts of each type of product to be made and where it will be produced. They also need to determine aggregate volumes through different distribution channels to different types of customers. Information required at this stage includes costs, capacities, and demand at an aggregate level over the planning horizon. Planning decisions also concentrate on analyzing information rather than collecting it. Planning IT tools are targeted toward people at middle to high level in a company.

3.Operational decisions

The operational level records transactions and handles time frames all the way down to the second. Operational IT systems are involved in setting weekly production and delivery schedules. Often, this phase requires less analytical work, especially once schedules are set. However, operation-al IT systems concentrate on executing and recording transactions. For example, operational IT systems may track whether the goods have been delivered or what is to be manufactured by a line during the next shift. This level is very informationintensive since it requires that information be available for every transaction in the supply chain. Operational IT systems are used by personnel such as shop floor workers and delivery schedulers who are directly participated in implementing supply chain transactions. Information collected at this level is the basis for all planning as well as strategic decisions.

10.4.2. IT in order processing

An order processing system can initiate such logistics activities as:

• Determining the transport mode, carrier, and loading sequence;

• Inventory assignment and preparing picking and packing lists;

• Warehouse picking and packing;

• Updating the inventory file, subtracting actual products picked;

• Automatically printing replenishment lists;

• Preparing shipping documents(a B/L if using a common carrier);

• Shipping products to the customer.

Other computerized order processing applications include maintaining inventory levels, and preparing productivity reports, financial reports, and special management reports.

Processing an order necessitates information flow from one department to another, as well as the referencing or accessing of several files or data bases(e.g., customer credit status, inventory availability, and transportation schedules). The information system may be either fully automated or manual; most are somewhere in between. Depending on the efficiency of the order processing system and the company Management Information System(MIS), the quality and speed of the information flow will differ, affecting the manufacturer’s ability to realize transportation consoli-dations and the lowest possible inventory levels. Manual systems are usually very slow and error prone. Such a system seriously restricts a company’s ability to carry out integrated logistics mana-gement specifically, to reduce total costs while keeping or improving customer service. The common problems include the inability to detect pricing errors, access timely credit information, or determine inventory availability. Negative impacts that occur as a result include invoice errors, payment delays, and rejection of an order due to false inventory information. Lost sales and higher costs combine to reduce the manufacturer’s profitability. Therefore, timely and accurate information is very important. Information delays hinder the completion of all activities that follow them in the process. Automating and integrating the order process can free time and eliminate the likelihood of information delays.

Automation can help managers integrate the logistics system and allow them to cut down costs through reductions in inventory and freight rates. The communications network is clearly an essen-tial factor in achieving least total cost logistics.

10.4.3. Customer service improvements

The improved quality of information resulted from the use of Internet has also benefited Supply Chain Management(SCM)a. Pricing accuracy is very important in order processing and the Inter-net provides companies with the ability to examine processes online before an order is placed. It also allows them to access the latest prices.

The above evaluation focuses on the use of Internet in SCM at the operational level. The Internet can also provide information, which can be used for strategies advantage, as opposed to operational purposes. For example, the online ordering of the Smart car, or the engineering of a customize care using multi-media tools in the showroom, is directly and electronically, associated with production planning. The production plan is shared with the supplier who receive orders in real-time from the manufacturer, using the supply chain wide information infrastructure. Consequently, the entire supply chain is involved in the concept. In addition, information is not only used for operational ordering purposes but also as strategic, longterm resource for competitiveness and further innovation in the supply chain. The information about customer preference can be mined and used to assist future product developments and innovation. Also,communications are not sequential but multi-directional, which overcomes the “bull-whip”effect.

10.4.4. Artificial Intelligence(AI)and Expert Systems(ES)

Developed from computer science, Artificial Intelligence(AI)is concerned with the concepts and methods of inference by a computer and the symbolic representation of the knowledge used in making inferences. The term intelligence covers a lot of cognitive skills, including the ability to solve problems, to learn, to understand language, and in general, to behave in a way that would be considered intelligent.

AI is a comprehensive term involving a number of areas, such as computer-aided instruction, voice synthesis and recognition, game playing systems, natural language translators, robotics, and Expert Systems(ES). Even though the number of applications of AI is limited currently, the potential in logistics is staggering. AI has been used to facilitate the design of automated warehousing systems, to configure computer systems and to identify material requirements, to group different sized shipments into logical entities for easier pallet building, and to aid in short-interval scheduling of warehouse, trucking, and manufacturing operations.

An ES is defined as a computer system that emulates the decision-making ability of a human expert. It is designed to solve complex problems by reasoning through bodies of knowledge, represented mainly as if–then rules rather than through conventional procedural code. ES can be applied to a variety of marketing and logistics problem categories, including interpretation, monitoring, debugging, repair, instruction, and control. More specifically, ES can be used in the following areas of logistics.

1.Transportation

Interpret economic and regulatory data and predict the impacts on transportation; Assess for hire/owned private fleet/leased fleet vehicle decisions and prescribe remedy; design vehicle routing to help managers minimize route time and increase asset utilization; plan delivery routing; monitor carrier performance and prescribe carriers in selection process; instruct traffic managers on proven carrier negotiation techniques.

2.Warehousing/Material handling systems

Evaluate alternative warehouse site locations and prescribe remedy; design specifications for advanced material handling systems for either a supplier or customer; design warehouse layout; plan and control receiving/shipping dock scheduling; monitor warehouse performance and suggest actions to improve performance; instruct receiving staff on quality control inspection procedures with regard to specific vendors and products.

3.Inventory

Interpret sales and other related data and predict product demand; evaluate inventory availability goals and uncertainty levels by location and determine safety stock levels; control system inventory levels; diagnose and debug demand forecast correction errors; instruct inventory staff regarding pro-cedures for taking physical inventory.

4.Purchasing

Interpret related data and predict future prices of essential materials; control material shortages; monitor material prices; monitor supplier performance and prescribe suppliers in sourcing and selection process; instruct buyers on sourcing new products/materials.

5.Packaging

Evaluate internal packing container arrangements and prescribe best arrangement of products; design product packaging in combination with physical and element environment; diagnose and debug package/carton malfunctions; monitor packaging department productivity/performance and prescribe improvements.

6.Information systems

Evaluate logistics communications needs and prescribe order transmittal methods/equipment; plan logistics information flow; plan and control backorder processing; monitor order management department performance and prescribe improvements; instruct order entry staff on order entry pro-cedures.

7.Customer service

Analyze customer information and prescribe future needs of key customer service; plan and control inventory allocations or product substitutions; monitor customer service performance and prescribe actions to improve customer service; instruct tracing staff on proven tracing methods regarding the carrier, product, or country.