Chapter 8 Procument and Supply Chain Management

8.4 Introduction to Supply Chain

8.4.1 What Is A Supply Chain

1. Definition of supply chain

A supply chain is a network between a company and its clients to produce and distribute a specific product to the final buyer. This network includes different activities, people (manufacturer, supplier, transporter, retailer, and customer), entities, information and resources. Within each enterprise, such as a manufacturer, the supply chain includes all functions involved in processing a customer’s request. These functions include, but are not limited to, new product development, marketing, operations, distribution, finance and customer service.

Let’s look at an example. Consider a customer walking into a Wal-Mart retail store to buy one bottle of detergent. The supply chain starts with the customer’s need for detergent. The next stage of this supply chain is the Wal-Mart retail store that the customer visits. Wal-Mart stocks its shelves using inventory that may have been supplied from a finished products warehouse that Wal-Mart manages or from a third-party distributor. The distributor in turn is stocked by the manufactur-er(e.g., Procter & Gamble, known as P&G). The P&G manufacturing plant receives raw material from various suppliers, who may themselves have been supplied by lower-tier suppliers. For example, the packaging material may come from Tenneco corporate and Tenneco may receive raw material from other suppliers to manufacture the packaging. This supply chain is shown in Figure 8.1.

Figure 8.1 An example of supply chain

A supply chain is dynamic and involves the constant flow of information, product and capital between different stages. Each stage of the supply chain carries out different process and interacts with other stages of the supply chain. Wal-Mart sells the product and provides pricing and availabi-lity information to the customer. The customer gives money to Wal-Mart. Wal-Mart transfers point-of-sale data and replenishment orders to the distribution center(DC), which fulfills the repleni-shment order by trucks back to the store. Wal-Mart then releases money to the distributor after the replenishment. In addition, the distributor also provides pricing information and sends delivery schedules to Wal-Mart. Similar information, material, and funds flows take place across the entire supply chain.

Another example is Dell supply chain. When a customer makes a purchase online from the webpage of Dell, the supply chain includes the customer, the webpage that takes the customer’s order, the Dell assembly plant, and all of Dell’s suppliers and the lower-tier suppliers. The webpage tells the customer such information as pricing, product variety and product availability. Having made a choice on a certain product, the customer inputs the order information and pays for the product. The customer may later return to the webpage to track the status of the order. Stages further up the supply chain use customer order information to fill the order. That process includes an additional flow of information, product, and funds between different stages of the supply chain.

The two examples indicate that the customer is an integral part of the supply chain. The main purpose for the existence of any supply chain is to meet the customer needs in the process of generating profits. Supply chain activities start with a customer order and end when a satisfied customer has paid for his/her purchase in this case. The term supply chain conjures up images of product, or supply, moving from suppliers to manufacturers to distributors to retailers to customers along a chain. It is crucial to visualize information, funds, and product flows along both directions of this supply chain. The term may also imply that only one entity is included at each stage. In practice, a manufacturer may receive raw material from various suppliers and then supply different distribu-tors. Hence, most supply chains are actually networks. It may be more precise to use the terms supply network or supply web to describe the structure of most supply chains.

A typical supply chain may include a series of stages as shown in Figure 8.2. The following parties such as customers, retailers, wholesalers/distributors, manufacturers and component/raw material suppliers are involved in the supply chain. It is noted that it is not necessary to include all the stages as shown in Figure 4.2 in all supply chains. The proper design of a supply chain will rely on both the customer’s needs and the roles of the stages involved in meeting those needs. In some special cases, such as Dell, a manufacturer may fill customer orders directly. Dell builds to order, that is to say, a customer order initiates manufacturing at Dell plant and Dell doesn’t need a retailer, wholesaler, or distributor in this supply chain. In other cases, such as the mail order company L.L. Bean(LLB) , manufacturers don’t respond to customer orders directly. LLB keeps a high inventory of products from which it fills customer orders. Compared to Dell supply chain, the supply chain of LLB has an extra stage(the retailer, LLB itself)between the customer and the manufacturer. For a small retail store, the supply chain may also include a wholesaler or distributor between the store and the manufacturer.

Figure 8.2 Supply chain stages

2. The goal of a supply chain

The goal of a supply chain is to maximize the overall value generated, which is thedifference between what the final product is worth to the customer and the efforts the supply chain makes in filling the customer’s request. For most commercial supply chains, the value will be significantly correlated with supply chain profitability, the difference between the sales revenue generated from the customer and the overall cost across the supply chain. For example, a customer buying a laptop from Dell pays $1500, which is the revenue the supply chain receives. Dell and other stages of the supply chain spend some money to convey information, produce components, store it, ship it, transfer money, etc. The difference between the $1500 that the customer paid and the sum of all costs incurred in the supply chain to produce and distribute the computer will be the supply chain profitability. It is the total profit to be shared across all supply chain stages. The higher the supply chain profitability, the more successful the supply chain. Therefore, the success of a supply chain should be evaluated in terms of supply chain profitability and not in term s of the profits at a separate stage.

We define the success of a supply chain in terms of supply chain profitability. The next logical step is to identify the sources of revenue and cost. For any supply chain, there is only one source of revenue, the customer. The customer is the only point that brings positive cash flow in a supply chain. Let’s see the case of Wal-Mart. The customer who buys detergent is the only one providing positive cash flow for the supply chain. All other cash flows are simply fund exchanges that occur within the supply chain, given that different stages have different owners. When Wal-Mart pays its supplier, it is taking a part of the funds the customer pays and passing it to the supplier. This cash transfer adds to the supply chain’s costs. All flows of information, product, or funds incur costs within the supply chain. So, proper management of these flows is a key to the success of a supply chain. The management includes the management of flows between and among different stages in a supply chain to maximize total profitability.

8.4.2 Decision Phases of A Supply Chain

Successful supply chain management requires several decisions in relation to the flows of information, products and funds. These decisions can be divided into three categories or phases, depending on the frequency of each decision and the time frame over which a decision phase has an impact.

1. Supply chain strategy or design

During this phase, an enterprise decides how to organize the supply chain. It determines the configuration of the supply chain and the processes at each stage. Decisions made during this phase are also called strategic supply chain decisions. Such decisions include the site location and capaci-ties of production and warehousing facilities, products to be manufactured or stored at different locations, transportation modes available along different transportation routes, and type of informa-tion system to be installed. An enterprise must make sure that the supply chain configuration supports its strategic goals during this phase. For example, Dell’s decisions regarding the site location and capacity of its manufacturing facilities, warehouses and supply sources are all supply chain design or strategic decisions. The decisions of supply chain design are typically drafted for a long-term(e.g., a matter of years)and are very expensive to alter on short time. Therefore, when enterprises make these decisions, they must take uncertainty into consideration in anticipated market conditions over the following few years.

2. Supply chain planning

Supply Chain Planning(SCP)is the forward-looking process of coordinating assets to optimize the delivery of goods, services and information from supplier to customer, balancing supply and demand. During this phase, enterprises define a series of operating policies that supervise short-term operations. The supply chain’s configuration considers real constraints within which planning must be done. Enterprises start the planning phase with a demand forecast for the coming years in different markets. Planning includes decisions about which markets will be supplied from which locations, the planned buildup of inventories, the subcontracting of manufacturing, the replenish-ment and inventory policies to be followed, the policies that will be enacted in relation to backup locations in case of a stockout, and the timing and size of marketing promotions. For example, Dell’s decisions about the markets that a specific production plant will supply and target production quantities at different plant locations need to be produced are categorized as planning decisions. Planning can provide some key parameters within which a supply chain will work over a specified period of time. In this phase, enterprises must consider the uncertainty in demand, exchange rates and competition while making decisions. Given a shorter time frame and reliable forecasts than the design phase, enterprises in the planning phase attempt to incorporate whatever flexibility may have been established in the design phase and exploit it to optimal performance in the shorter term.

3. Supply chain operation

During this phase, the time horizon is weekly or daily, and enterprises make decisions on individual customer orders. At the operational level, supply chain configuration is regarded fixed and planning policies already defined. The aim of supply chain operations is to carry out the operating policies in the best possible way. During this phase, enterprises allocate individual orders to inventory or production, set a date that an order is to be filled, generate pick lists at a particular warehouse, allocate an order to a specific shipping mode and shipment, set delivery schedules of trucks, and place replenishment orders. Since operational decisions are made in the short term(e.g., minutes, hours, or days), there is often less uncertainty about demand information. The objective during the operation phase is to reduce the uncertainty and optimize performance subject to the constraints established by the configuration and planning policies.

The design, planning and operation phases of a supply chain have significant impact on overall profitability and success. In the case of Dell Computer, Dell performed poorly in 1993, and its stock price dropped dramatically, which led the upper management of Dell to focus on improving the design, planning and operation of the supply chain, and in turn, the performance was significantly improved. Subsequently, both profitability and the stock price have increased because of this increase in performance.

8.4.3 Process View of A Supply Chain

A supply chain is a sequence of processes and flows that incur within and between different supply chain stages and combine to meet a customer’s need for a product. The following are two different ways to view the processes performed in a supply chain:

(1)Cycle view. The processes in a supply chain are classified into a set of cycles, each performed at the interface between two successive stages of a supply chain.

(2)Push/Pull view. The processes in a supply chain are classified into two categories depending on whether they are implemented in response to a customer order or in anticipation of customer orders. Pull processes are initiated by customer orders, while push processes are initiated and performed by anticipation of customer orders.

1. Cycle view of supply chain processes

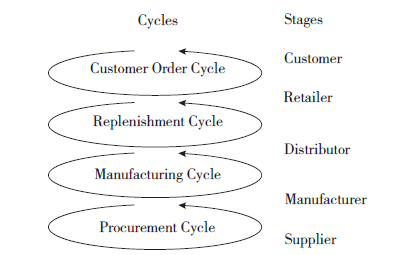

Based on the five stages in a supply chain shown in Figure 8.2, all supply chain processes can be broken down into four process cycles, including customer order cycle, replenishment cycle, manu-facturing cycle and procurement cycle (Figure 8.3).

Each cycle occurs at the interface between two successive stages of the supply chain. Therefore, the five supply chain stages generate four supply chain process cycles. It is noted that not every supply chain will have all four cycles clearly separated. A sports supply chain in which a retailer saves finished-products inventories and places replenishment orders either with the manufacturer or the distributor is likely to have all four cycles separated. Dell, in contrast, sells directly to customers, thus bypassing the retailer and distributor.

Figure 8.3 Supply chain process cycles

A cycle view of the supply chain is very important when making operational decisions, as it can clearly define the roles and responsibilities of each member within the supply chain. The cycle view also provides clarity, for instance, when installing information systems to support supply chain operations, since process ownership and goals are clearly defined.

(1)Customer order cycle

The customer order cycle occurs at the customer/retailer interface and includes all processes directly involved in receiving and filling the customer’s order. Typically, the customer initiates this cycle at a retail store, and the cycle mainly involves filling customer demand. The retailer’s interaction with the customer begins when the customer arrives or contact is initiated and ends when the customer receives the product.

(2)Replenishment cycle

This cycle occurs at the retailer/distributor interface and includes all processes involved in replenishing retailer inventory. It is initiated when a retailer places an order to replenish inventories to meet future demand. The replenishment cycle may be triggered at any point of the production, distribution, or sales cycle depending on what works best for a specific industry. For example, a business may wish to have the replenishment cycle recur while there is still enough stock on hand to meet orders for the next few days; or it may put off replenishment until a specific minimum order quantity is reacheda.

The replenishment cycle is similar to the customer order cycle except that the retailer is now the customer. The aim of replenishment cycle is to replenish inventories at the retailer at minimum cost while providing the necessary product availability to the customer.

(3)Manufacturing cycle

This cycle typically occurs at the distributor/manufacturer(or retailer/manufacturer) interface and includes all processes involved in replenishing distributor(or retailer) inventory. This cycle is initiated by customer orders, replenishment orders from a retailer or distributor, or by the prediction of customer demand and current product availability in the manufacturer’s finished-products warehouse.

Generally, a manufacturer produces several types of products and fills customer demand from different sources. One extreme in a manufacturing cycle is an integrated steel mill that collects orders that are similar enough to enable the manufacturer to produce in large quantities. In such case, the manufacturing cycle is responding to customer demand.

Another extreme includes some types of consumer products that enterprises must produce in anticipation of future demand. In this case, the manufacturing cycle is anticipating customer demand.

(4)Procurement cycle

The procurement cycle occurs at the manufacturer/supplier interface and includes a series of steps to ensure that materials are available for manufacturing based on schedule. It starts with identifying the need for a given component or raw material, moves through the process of purchase and delivery, and winds up at renewal, where people decide if they need more of the product. Compo-nent orders are dependent on the production schedule. Therefore, it is important that suppliers be linked to the manufacturer’s production schedule. Of course, if a supplier’s lead times are long, the supplier has to produce to forecast because the manufacturer’s production schedule may not be fixed that far in advance.

2. Push/Pull view of supply chain processes

All processes in a supply chain can fall into one of the two categories, depending on the timing of their implementation relative to customer demand. In the pull processes, implementation is initiated in response to a customer order. Push processes are those that are implemented in anticipation of future customer orders. When executing a pull process, customer demand is known with certainty. However, when executing a push process, demand is not known and must be predicted. Pull processes may also be called reactive processes as they react to customer demand. On the other hand, push processes may also be called speculative processes since they respond to speculated(or predicted)rather than actual demand. The push/pull boundary in a supply chain separates push processes from pull processes. For example, at Dell, the beginning of personal laptops assembly represents the push/pull boundary. All processes before laptop assembly are push processes, and all processes after and including assembly are initiated in response to a customer order and are thus called pull processes.

A push/pull view of the supply chain is very important when making strategic decisions in relation to supply chain design. This view forces a more global consideration of supply chain processes since they relate to a customer order. Such a view may, for example, result in responsibility for some processes being passed on to a different stage of the supply chain if making this transfer allows a push process to become a pull process.

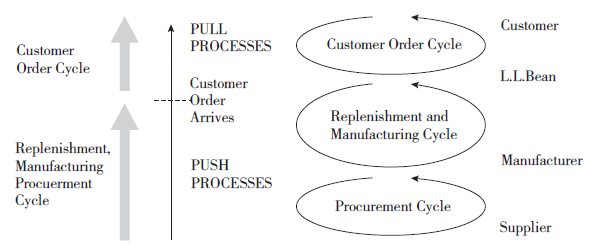

Let’s consider two different supply chains that we have talked about and relate them to the push/pull and the cycle views. One supply chain is a mail order company like LLB that receives customer orders through its telemarketing center or company web site. The other one is a build-to-order computer manufacturer like Dell. LLB carries out all processes in the customer order cycle after the customer arrives. All processes that are part of the customer order cycle are thus pull processes. Order fulfillment incurs from product inventory that is built up in anticipation of customer orders. The aim of the replenishment cycle is to ensure product availability when a customer order arrives. All processes in the replenishment cycle are implemented in anticipation of demand and are thus push processes. The same holds true for processes in the manufacturing and procurement cycle. Actually, raw material like fabric is usually ordered six to nine months before customer demand is expected. Manufacturing itself starts three to six months before the point of sale. All processes in the manufacturing and procurement cycle are thus push processes. The processes in the LLB supply chain break up into pull and push processes, as shown in Figure 8.4.

Figure 8.4 Push/Pull processes for the L.L. Bean supply chain

The situation is quite different for a build-to-order computer manufacturer like Dell. Dell doesn’t sell through a retailer or distributor but rather directly to the customer. Demand is not filled from finished-product inventory but from production. The arrival of a customer order initiates production in final assembly. The manufacturing cycle is therefore part of the customer order fulfillment process in the customer order cycle.

One obvious difference between the two supply chains discussed previously is that the Dell supply chain has fewer stages and more pull processes than the LLB supply chain.