Chapter 2 Transportation

2.6 Containerization

Containerization is a system of intermodal freight transport using intermodal containers (also called shipping containers and ISO containers) made of weathering steel. Containers are the boxed utilized for intermodal product storage and movement between motor freight, railroads, and water transportation. They can be loaded and unloaded, stacked, transported efficiently over long distances, and transferred from one mode of transport to another—container ships, rail transport flatcars, and semi-trailer trucks—without being opened. Thus containers are particularly suitable for multimodal transportation.

If the goods have to pass through three stages of transportation, namely, they are first carried by land, then by sea, and finally by land, they will travel in the same container from the place of loading to that of discharge and the physical labor as well as the cost of conveying them from one vehicle of transportation to the next are saved. In addition, the danger of theft and pilferage is reduced. The business courses in container transport are that the exporter, having made arrangements with a forwarder or directly with the office of a container shipping line, sends his goods to the nearest container loading depot of the forwarder or shipping line. These depots, called container freight stations (CFSs) are situated in all major industrial centers inland or at the ports. If the exporter intends to fill a full container load (FCL), the forwarder or shipping line will be prepared to send an empty container to the exporter of loading. If the exporter has arranged for the delivery of the goods to the overseas buyer’s place of business, the container would be a door-to-door container.

It is important that the door-to-door container is properly sealed with the carrier’s seal, this is sometimes done by the shipper, and in other cases by the driver of the collective vehicle. The exporter should make sure of this, because if there is a claim for shortage of or damage to the cargo carried in the container, the state of the carrier’s seal may allow an inference of what has happened. If it is broken, it would indicate that the cargo has been tampered with during the transport. If the cargo is less than a full container load (LCL), the exporter sends it to the container freight station, where it will be consolidated with the goods of other exporters in a groupage container. On arrival at the place of destination it will be taken to a container freight station, where it will be “de-grouped”, i.e., the parcels contained therein will be separated and delivered to the various consignees.

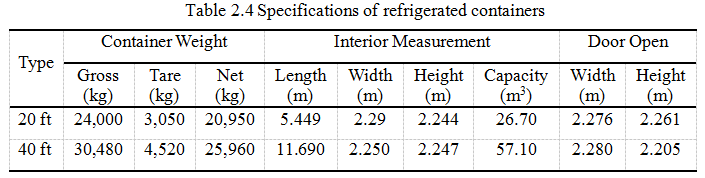

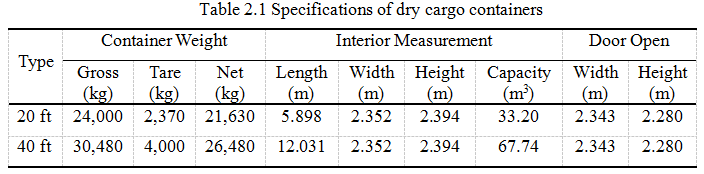

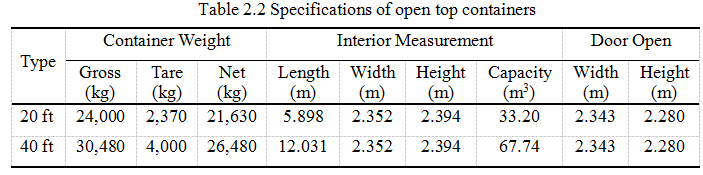

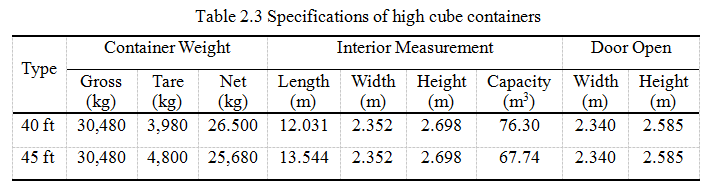

Container specifications and capacities vary slightly between different carriers and container manufactures. Following specifications can be used as a close approximate only:

Dry Cargo Containers: Dry containers 20ft and 40ft (general purpose) are manufactured from either aluminum or steel. They are suitable for most types of cargo. Aluminum dry containers have a slightly larger payload than steel, and steel dry containers have a slightly larger internal cube (see Table 2.1).

Open Top Containers: They are suitable for over height cargo loading from top side, e.g., by crane loading from door side, e.g., with cargo hanging from overhead tackle. Door header can be swung out on all open containers (see Table 2.2).

High Cube Containers: With high cube containers, you gain an extra foot in height compared with general-purpose containers. Ideal for light, voluminous cargo or bulky cargo. These extra volume containers come in 40 ft and 45 ft sizes in steel (see Table 2.3).

Refrigerated Containers: Refrigerated containers - also known as reefers – are ISO shipping containers with an integral refrigeration unit, which allows for the transportation of temperature sensitive cargo. ISO containers are built to extremely high standards to be robust and endure the demands of transportation by road, rail and sea. They rely on a power from a land based site, but can be powered in transit by a diesel powered generator which attaches to the container. Refrigerated containers can be used for either storage or shipping. Specifications of refrigerated containers was listed in Table 2.4.