-

1

-

2

Chapter 4 Inventory

4.3 Introduction to Inventory

Inventoryorstock refers to the goods and materials that a business holds for theultimate purpose of resale (or repair). Inventory management is a scienceprimarily about specifying the shape and placement of stocked goods. It isrequired at different locations within a facility or within many locations of asupply network to precede the regular and planned course of production andstock of materials. Formulation of an inventory policy requires anunderstanding of the role of inventory in manufacturing and marketing.Inventory serves five purposes within the firm:

(1) Enable economies of scale

Inventoryis required if a firm is to realize economies of scale in purchasing,transportation, and/or manufacturing. For example, raw materials inventory isnecessary if the manufacturer is to take advantage of the per-unit pricereductions associated with volume purchases. Purchased materials have a lowertransportation cost per unit if ordered in larger volumes. This lower per-unitcost results because truckload and full railcar shipments receive lowertransportation rates than smaller shipments of less than truckload (LTL) orless than carload (LCL) quantities.

Theproduction of large quantities, however, may require that some of the items becarried in inventory for a significant period of time before they can be sold.The production of large quantities may also prevent timely and responsiverecovery on items that are stocked out, since large production runs mean thatitems will be produced less frequently. The cost of maintaining this inventorymust be compared to the production savings realized. Although frequentproduction changeovers reduce the quantity of inventory that must be carried,and shorten the lead time that is required in the event of a stockout, theyrequire time that could be used for manufacturing a product.

(2) Balancing supply and demand

Seasonalsupply and/or demand may make it necessary for a firm to hold inventory. Forexample, a producer of a premium line of boxed chocolates experiencessignificant Sales volume increases at Christmas, Valentine’s Day, Easter, andMother’s Day. The cost of establishing production capacity to handle the volumeat these peak periods would be substantial. In addition, substantial idlecapacity and wide fluctuations in the labor force would result if the companywere to produce to demand. The decision to maintain a relatively stable workforce and produce at a somewhat constant level throughout the year createssignificant inventory buildup at various times during the year, but at a lowertotal cost to the firm. The seasonal inventories are stored in a freezerwarehouse that was built adjacent to the plant.

On the other hand, demand for a product maybe relatively stable throughout the year, but raw materials may be availableonly at certain times during the year. Such is the case for producers of cannedfruits and vegetables. This makes it necessary to manufacture finished productsin excess of current demand and hold them in inventory.

(3) Specialization in manufacturing

Inventory makes it possible for each of afirm’s plants to specialize in the products that it manufactures. The finishedproducts can be shipped to large mixing warehouses, from which customer ordersand products for field warehouses can be shipped. The economies that resultfrom the longer production runs, as well as savings in transportation costs,more than offset the costs of additional handling. Companies such as WhirlpoolCorporation have found significant cost savings in the operation ofconsolidation warehouses that allow the firm to specialize manufacturing byplant location. The specialization by facility is known as focused factories.

(4) Protection from uncertainties

Inventory is also held as protection fromuncertainties. Raw materials inventories in excess of those required to supportproduction can result from speculative purchases made because managementexpects a future price increase or future supply is in doubt due to a potentialstrike, for example. Other reasons include seasonal availability of supply,such as in the case of fruits or vegetables for canning, or a desire tomaintain a source of supply. Regardless of the reason for maintaining a rawmaterials inventory, the costs of holding the inventory should be compared tothe savings realized or costs avoided by holding it. Work-in-process inventoryis often maintained between manufacturing operations within a plant to avoid ashutdown if a critical piece of equipment were to break down, and to equalizeflow, since not all manufacturing operations produce at the same rate.

Finally, finished goods inventory can be usedas a means of improving customer service levels by reducing the likelihood of astockout due to unanticipated demand or variability in lead time. If theinventory is balanced, increased inventory investment will enable themanufacturer to offer higher levels of product availability and less chance ofa stockout. A balanced inventory is one that contains items in proportion toexpected demand

(5) Inventory as a buffer

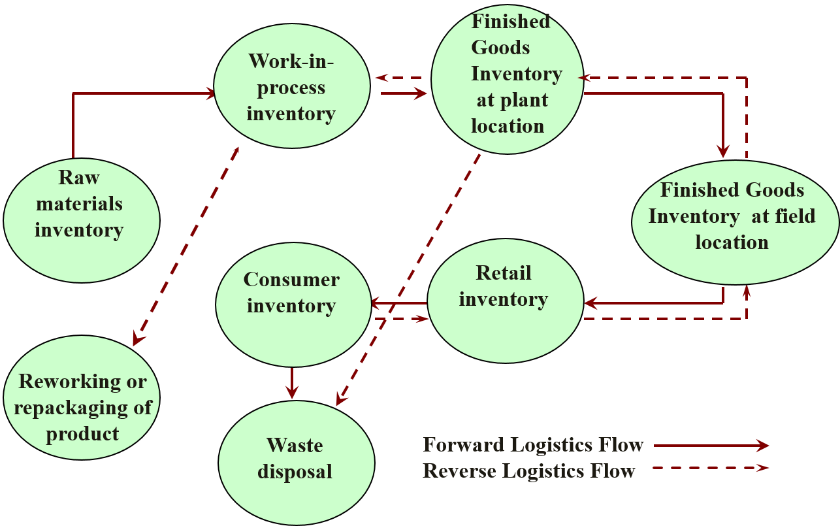

Inventory is held throughout the channel ofdistribution to act as a buffer for the following critical interfaces:supplier-procurement (purchasing); procurement production; productionmarketing; marketing distribution; distribution-intermediary andintermediary-consumer/user. Because channel participants are separatedgeographically, it is necessary for inventory to be held throughout the channelof distribution in order to successfully achieve time and place utility.Because channel participants are separated geographically, it is necessary forinventory to be held throughout the channel of distribution in order tosuccessfully achieve time and place utility. Figure 2.2 shows the typicalinventory positions in a supplier manufacturer-intermediary -consumer channelof distribution. Raw materials must be moved from a source of supply to themanufacturing location, where they will be input into the manufacturingprocess. In many cases this will require holding work-in-process inventory.

Figure 4.1 Logistics flow-Typicalinventory positions in a supplier manufacture-intermediary-consumer channel ofdistribution