Chapter 3 Warehousing

3.4 Warehousing Operations

Warehousing serves an important role in a firm’s logistics system. In combination with other activities, it provides the firm’s customers with an acceptable level of service. The obvious role of warehousing is to store products. However, warehousing provides breakbulk, consolidation, and information services as well. These activities emphasize product flow rather than storage. Fast and efficient movement of large quantities of raw materials, component parts, and finished goods through the warehouse, coupled with timely and accurate information about the products being stored, is the goal of every logistics system.

3.4.1 Functions of Warehousing

Warehousing has three basic functions: movement, storage, and information transfer.

(1) The function of movement can be further divided into four handling activities: receiving, transfer, order selection, and shipping.

The receiving activity includes the physical unloading of products from the transportation carrier. It also includes the updating of warehouse inventory records, inspection for damage, and verification of the merchandise count against orders and shipping records. Transfer involves the physical movement of the product into the warehouse for storage, movement to areas for specialized services such as consolidation, and movement to outbound shipment. Customer order selection is the major movement activity and involves regrouping products into the assortments customer’s desire. Packing slips are also made up at this point. The last movement activity, shipping, consists of product staging and physically moving the assembled orders into carrier equipment, adjusting inventory records, and checking on orders to be shipped.

(2) The function of storage can be performed on a temporary or a semi-permanent basis. Temporary storage emphasizes the movement function of the warehouse and includes only the storage of product necessary for basic inventory replenishment. Temporary storage is required regardless of the actual inventory turnover. The extent of temporary inventory storage depends on the design of the logistics system and the variability experienced in lead time and demand. Semi-permanent storage is the storage of inventory in excess of that required for normal replenishment. It can also be referred to as buffer or safety stock. The most common conditions leading to semi-permanent storage are a) seasonal demand; b) erratic demand; c) conditioning of products such as fruits and meats; d) speculation or forward buying; and e) special deals, such as quantity discounts.

(3) The function of information transfer occurs simultaneously with the movement and storage functions. Management always needs timely and accurate information as it attempts to administer the warehousing activity. Information on inventory levels, throughput levels, stock keeping locations, inbound and outbound shipments, customer data, facility space utilization, and personnel is vital to the successful operation of a warehouse.

3.4.2 Typical Activities Performed in a Warehouse

In summary, a warehouse will perform the following typical activities:

Receiving is the first stage of the warehousing process. It includes physically accepting material, unloading that material from the inbound transportation mode, staging, verifying quantity and condition of the material, and documenting this information as required.

Put-away is the physical process of taking goods received and placing them within the warehouse in the locations where they are to be stored.

Storage is the most basic warehousing activity. It is defined as the depositing of goods in a facility for safekeeping.

Replenishment is the process of relocating goods from a bulk storage area to an order-pick storage area. An important warehousing task is to keep track of inventory levels efficiently so that replacement stocks can be obtained.

Order selection is also called order picking. It involves the accurate and timely selection of product for shipment from the warehouse.

Successful completion of all of the warehousing activities already mentioned eliminates the need for checking. However, errors and mistakes do occur within any warehouse operation, and it is usually necessary to conduct a check of previous activities. This function is analogous to the quality-control function in manufacturing.

Packaging and marking involves the preparation of the goods for shipment. Products are placed in boxes, cartons, or other containers, placed on pallets, and/or stretch-wrapped (the Process of wrapping products in a plastic film), and are marked with information necessary for shipment, such as origin, destination, shipper, consignee and package contents.

Staging and consolidation is concerned with preparing the goods for shipment and usually takes place on the loading dock or staging area of the warehouse.

The actual loading and movement of the product occurs in the shipping activity.

The final function, clerical/administrative, occurs in conjunction with all warehousing activities. Each activity must be administered effectively and efficiently. In addition, a large number of clerical duties must be performed in conjunction with each warehouse activity. In spite of numerous attempts by firms to reduce the paperwork flow involved in the logistics process, the amount of paperwork is still significant. For this reason, and many others, firms have attempted to automate the clerical function whenever possible. During all phases, housekeeping chores as well as equipment maintenance will take place.

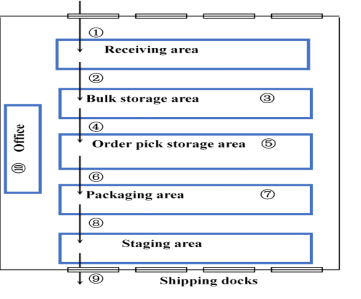

Figure 2.1 displays most of the activities typically performed in a warehouse. The numbers in the figure correspond to the preceding list of items.

Within the warehouse it is important to eliminate any inefficiencies in movement, storage, and information transfer. Today’s competitive marketplace demands more precise and accurate handling, storage, and retrieval systems, as well as improved packaging and shipping systems. It is therefore vital for a warehouse operation to have the optimal mix of manual (non-automated) and automated handling systems.

Figure 3.1 Typical activities performed in a warehouse