Chapter 1 Introduction to Logistics

1.3 Fundamental of Logistics

1.3.1 The Definition of Logistics

“In a general business sense, logistics is the management of the flow of things between the point of origin and the point of consumption in order to meet requirements of customers or corporations.”

—Wikipedia

“Logistics is defined as a business planning framework for the management of material, service, information and capital flows. It includes the increasingly complex information, communication and control systems required in today's business environment.”

— Logistix Partners Oy, Helsinki, FI, 1996

“Logistics is the process of planning, implementing, and controlling the efficient, cost effective flow and storage of raw materials, in-process inventory, finished goods and related information from point of origin to point of consumption for the purpose of meeting customer requirements.”

— Canadian Association of Logistics Management

Since there are some differences in the definitions, to avoid potential misunderstanding of the meaning of logistics, this book adopts the authoritative definition provided by the Council of Supply Chain Management Professionals (CSCMP, formerly known as Council of Logistics Management), the preeminent worldwide professional association dedicated to the advancement and dissemination of research and knowledge on supply chain management. The definition is as follows:

“Logistics is the process of planning, implementing, and controlling the efficient, effective flow and storage of goods, services, and related information from point of origin to point of consumption for the purpose of conforming to customer requirements.” Note that this definition includes inbound, outbound, internal, and external movements, and return of materials for environmental purposes.

—Council of Supply Chain Management Professionals

1.3.2 Historical Development of Logistics

Logistics has been playing a fundamental role in global development for almost 5,000 years now. Since the construction of the pyramids in ancient Egypt, logistics has made remarkable strides. Around 2700 B.C., material handling technology was used in pyramid construction. Blocks of stone weighing several tons were transported and assembled at the construction site. Even today, we still cannot fully explain how this level of precision was achieved using the hoisting equipment and means of transport available at that time.

Logistics was first examined in scholarly writing in the early 1900s. John Crowell (1901) discussed the costs and factors affecting the distribution of farm products in the U.S. government’s Report of the Industrial Commission on the Distribution of Farm Products. Later, Arch Shaw in his An Approach to Business Problems (1916) discussed the strategic aspects of logistics. In the same year, L. D. H. Weld introduced the concepts of marketing utilities (time, place, possession) and channels of distribution. In 1922, Fred Clark identified the role of logistics in marketing. In 1927, the term logistics was defined in a way similar to its use today.

With the onset of World War II, logistics received prominent recognition in military operations as it contributed to the effective distribution of machinery and supplies to troops. Fleet Admiral King in his reports to the Secretary of the Navy summed it up as follows: “The war has been variously termed a war of production and a war of machines. Whatever else it is, so far as the United States is concerned, it is a war of logistics.” The United States military ensured that the services and supplies were provided at the right time and at the right place. It also tried to provide these services when and wherever required, in the most optimal and economical manner. The best available options to do the task were developed. This also gave birth to several military logistics techniques which are still in use, albeit in a more advanced form.

In 1956, the invention of the sea container by the American Malcom P. McLean changed production conditions for nearly all industries around the world. Even today, the sea container continues to ensure that harbors gain major contracts, new countries and regions experience commercial booms, markets arise and products from all parts of the world can be bought and sold at reasonable prices. In this way, the container has significantly contributed to globalization.

Beginning in the late 1970s and continuing throughout the 1980s, logistics management was significantly affected by deregulation of the transportation industry. The Airline Deregulation Acts of 1977 and 1978, Staggers Rail Act of 1980, Motor Carrier Act of 1980, and Shipping Act of 1984 removed or modified the existing economic sanctions on air, rail, motor, and ocean transport, respectively. The impact on carriers and shippers has been profound. In the case of carriers, deregulation has resulted in increased competition; greater pricing freedom (i.e., establishing and modifying rates); more flexibility in routing and scheduling; an increased need to become marketing oriented; and a need to be creative in terms of marketing mix offerings. Shippers have more carriers from which to choose. New and varied types of services are now available. Most rates are now negotiated and involve long-term agreements. Service levels provided by carriers vary widely depending on the origin/destination combination.

Computer technology and distribution software are two other factors that have caused businesses to become more interested in logistics management. The development of computer technology, particularly the microcomputer, has allowed executives to manage and implement logistics management much more effectively and efficiently. Firms can become much more cost efficient because of the speed and accuracy of the computer; they can use sophisticated techniques (e.g., MRP, MRPII, DRP, DRPII, Kanban, and Just-in-Time) to manage and control activities such as production scheduling, inventory control, order processing, and others. In fact, such advances, and the resulting impact on the firm’s marketing, production, and financial activities, have been instrumental in creating top management awareness of logistics.

Around 1990, the quick response (QR) and efficient consumer response (ECR) technologies were developed and applied by many retail and wholesale companies. These technologies had a major impact on logistics. As a result of this technology, distribution centers are tasked with moving goods instead of storing them. This allows companies to accelerate reaction times to market developments and to set up efficient goods-supply systems.

Today, supply chain management is viewed as a holistic consideration of key business processes that extend from the vendor’s supplier to the end user. Accordingly, supply chain management is an extremely interactive, complex system requiring simultaneous monitoring of many conflicting objectives. With the fierce global competitiveness, efficient logistics creates a crucial competitive edge for companies that are expanding in global markets. Successful logistics efforts in international supply chains can fuel the development of global markets.

1.3.3 Logistics Related Activities

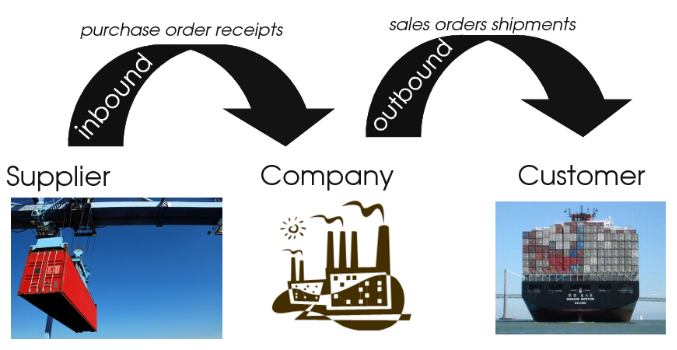

A basic distinction in the nature of logistics activities is between inbound and outbound logistics (Figure 1.1).

Inbound logistics is one of the primary processes of logistics, concentrating on purchasing and arranging the inbound movement of materials, parts, and/or finished inventory from suppliers to manufacturing or assembly plants, warehouses, or retail stores.

Outbound logistics is the process related to the storage and movement of the final product and the related information flows from the end of the production line to the end user.

Figure 1.1 Inbound vs. outbound logistics

The logistics activities can also be classified into key activities and support activities.

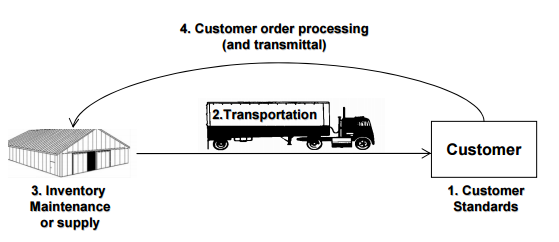

(1) Key components of logistics – key activities

The core activities take place in every supply channel. They contribute the most to the total cost of logistics or they are essential to the effective coordination and completion of the logistics task. These are mentioned as below:

Customer service (typically defined by marketing)

Transportation

Inventory management

Information flows and order processing

Figure 1.2 Key logistics activities

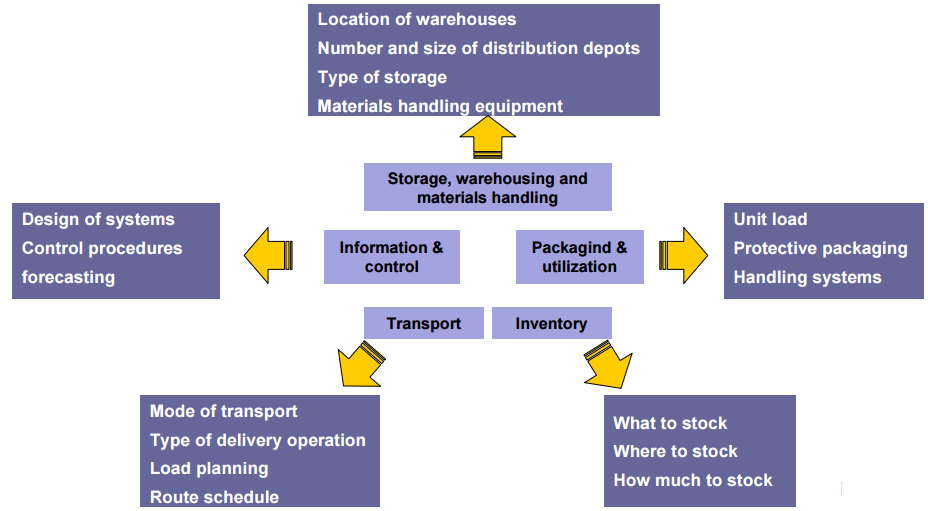

(2) Key components of logistics – support activities

Support activities vary from company to company. A comprehensive list includes:

Warehousing (Space determination, stock layout, configuration, stock placement)

Materials handling (equipment selection & replacement policies, order-picking procedures, stock storage & retrieval)

Purchasing (supply source selection, purchase timing, purchase quantities)

Protective packaging (designed for handling, storage, protection from loss/damage)

Cooperate with production/operations (specify aggregate quantities, sequence & time production output, schedule supplies)

Information maintenance (info collection, storage & manipulation, data analysis, control procedures)

The illustration of key components of logistics is shown in Figure 1.3.

Figure 1.3 Illustration of key components of logistics

1.3.4 The Objectives of Logistics

The main economic objectives of logistics include: (1) the reduction of inventory, (2) the economy of freight, (3) obtaining an maintaining reliability and consistency in delivery performance, (4) insuring minimum damage to products, and (5) a quicker and faster response to customers’ demands.

(1) Reduction of inventory

Inventory is considered one of the key factors, which can affect the profit of an enterprise to a great extent. In the traditional system, firms had to carry lot of inventory for satisfying the customer and to ensure excellent customer service. But, when funds are blocked in inventory, they cannot be used for other productive purposes. These costs will drain the enterprise's profit. Logistics helps in maintaining inventory at the lowest level, and thus achieving the customer goal. This is done through small, but frequent supplies.

(2) Economy of freight

Freight is a major source of cost in logistics. This can be reduced by following measures like selecting the proper mode of transport, consolidation of freight, route planning, long distance shipments, etc.

(3) Reliability and consistency in delivery performance

The materials required by the customer must be delivered on time, not ahead of the schedule or behind the schedule. Proper planning of the transportation modes, with availability of inventory should ensure this.

(4) Minimum damage to products

Sometimes products may be damaged due to improper packing, frequent handling of consignment, and other reasons. This damage adds to the logistics cost. The use of proper logistical packaging, mechanized material handling equipment, etc. will reduce this damage.

(5) Quicker and faster response

A firm must have the capability to extend service to the customer in the shortest time frame. By utilizing the latest technologies in processing information and communication will improve the decision making, and thus enable the enterprise to be flexible enough so that the firm can fulfill customer requirements, in the shortest possible time frame.

1.3.5 7R Theory of Logistics

The philosophy for the “seven rights” initiative applies to logistics. The “seven rights” include:

Getting the right product,

In the right quantity,

In the right quality,

To the right place,

At the right time,

In the right condition,

At the right price.

With manual processes, errors are more likely to occur in the picking, packing and shipping operation each time an order is filled. With the “seven rights” in place, the focus is on achieving cost efficiencies, reducing waste and increasing the level of customer service provided by the organization.

How critical are the “seven rights”? Today’s buyer has little time, budget or tolerance for error. With respect to consumer goods, brick and mortar companies(实体公司) are constantly faced with the competition of their online counterparts simply due to the “time” it takes to make a purchase. Brick and mortar and online organizations have one thing in common: Both need to store product in a warehouse and have the ability to accurately and efficiently pull goods from inventory to fill orders.

Sound simple? One order at a time can easily be managed, but what about 500 or 5000 orders going out the door each day? Pickers can easily pull information, but what about the process of shipping? By integrating technology with the order filling process, efficiencies will increase, labor costs will reduce, and transportation costs will be controlled through a finely-tuned, highly-automated process.

To varying degrees, the logistics function also includes sourcing and procurement, production planning and scheduling, packaging and assembly, and customer service. It is involved in all levels of planning and execution strategic, operational and tactical. Logistics management is an integrating function which coordinates and optimizes all logistics activities, as well as integrates logistics activities with other functions, including marketing, sales, manufacturing, finance, and information technology.